Turning Complex Dynamics into clear design decisions

A leading engineering consultancy specializing in advanced CFD, FEA, and Predictive Analytics solutions to solve the most complex challenges

At Segmenta, we help engineers and project teams make smarter design decisions

Through precision Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), and Data Science. From fluid flow and thermal management to structural integrity and stress analysis, our insights reduce risk, cut costs, and accelerate innovation.

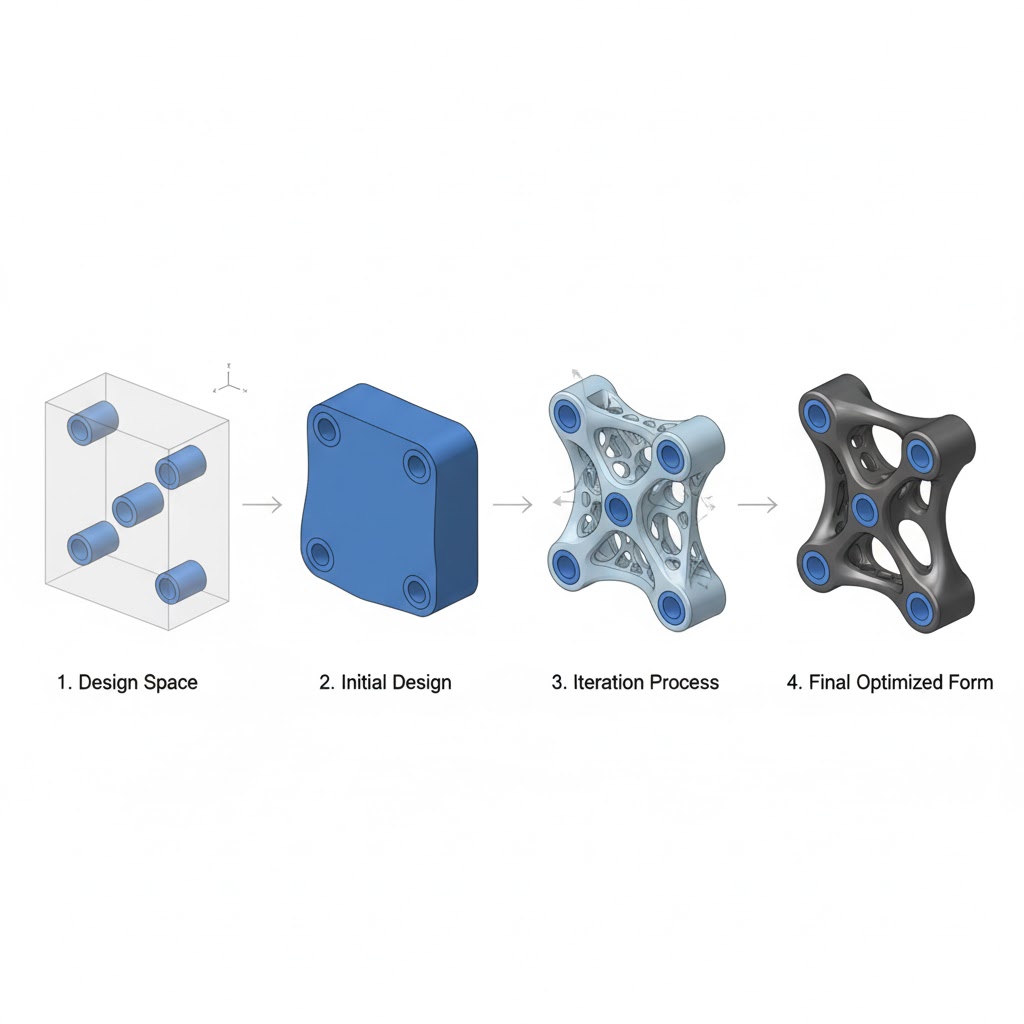

Generative Design

Algorithm-driven design placing material only where needed, creating lightweight organic structures optimized for additive manufacturing.

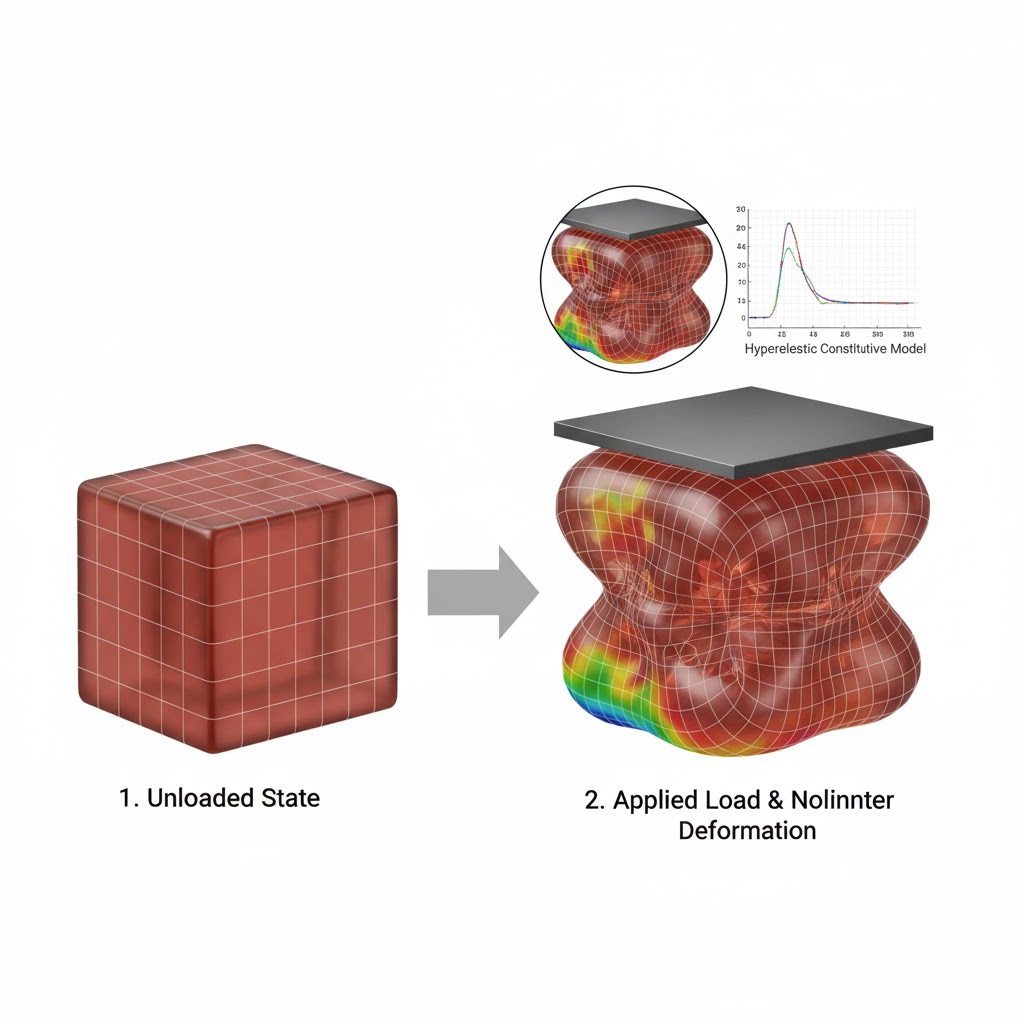

Advanced Material Modeling

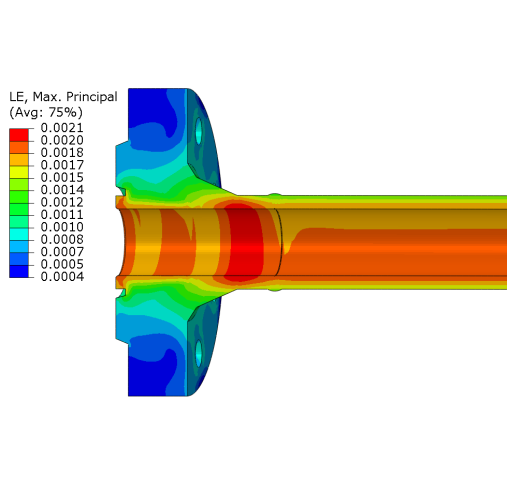

Simulating complex non-linear materials including hyperelastic rubbers, biological tissues, polymers, and shape-memory alloys for accurate behavior prediction.

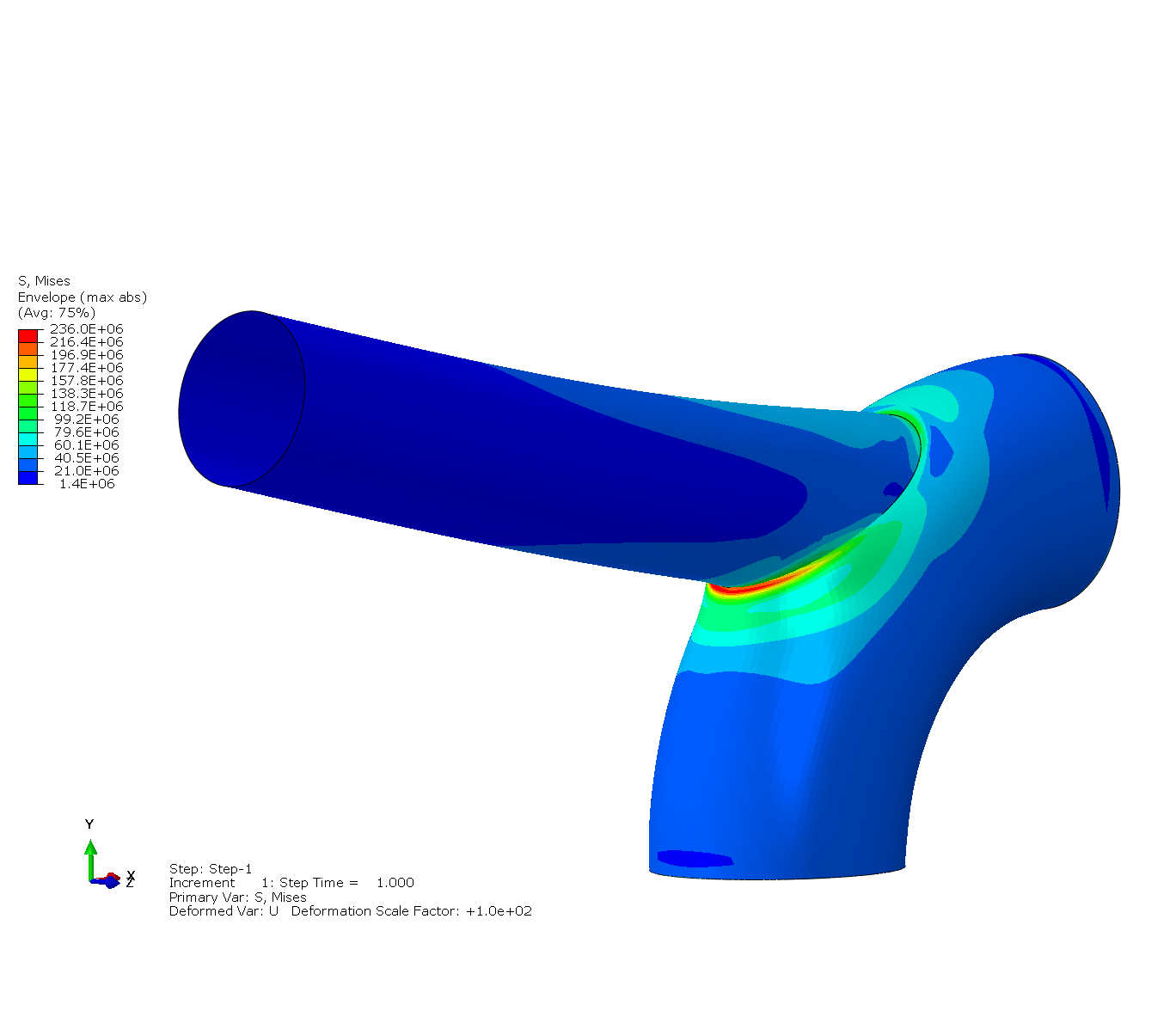

Multiphysics Simulation

Solving coupled physics problems: Fluid-Structure Interaction, thermal-electric coupling in batteries, and vibro-acoustic analysis.

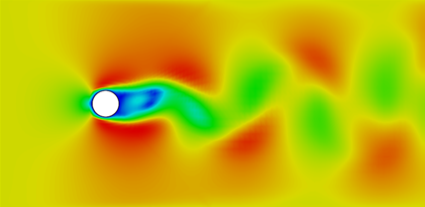

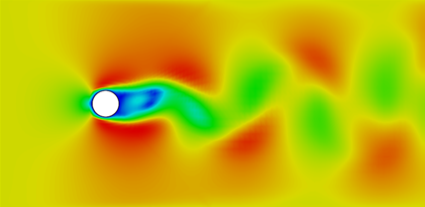

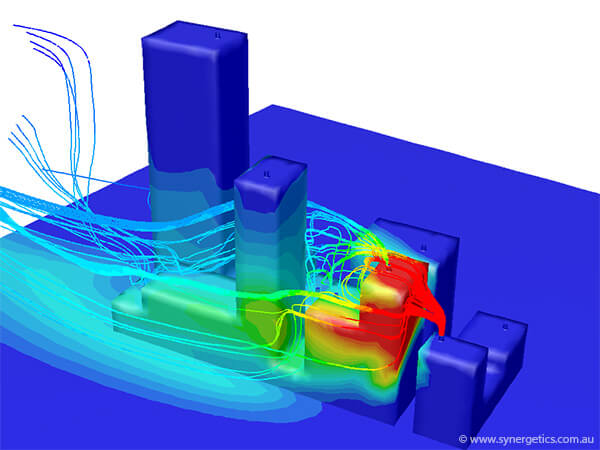

Computational Fluid Dynamics (CFD)

Simulation of fluid flow and heat transfer to optimize designs and processes.

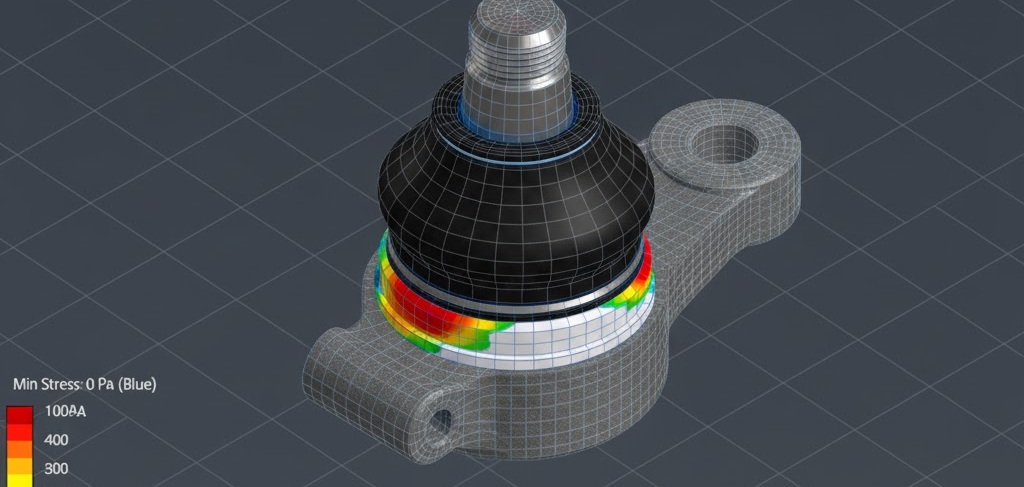

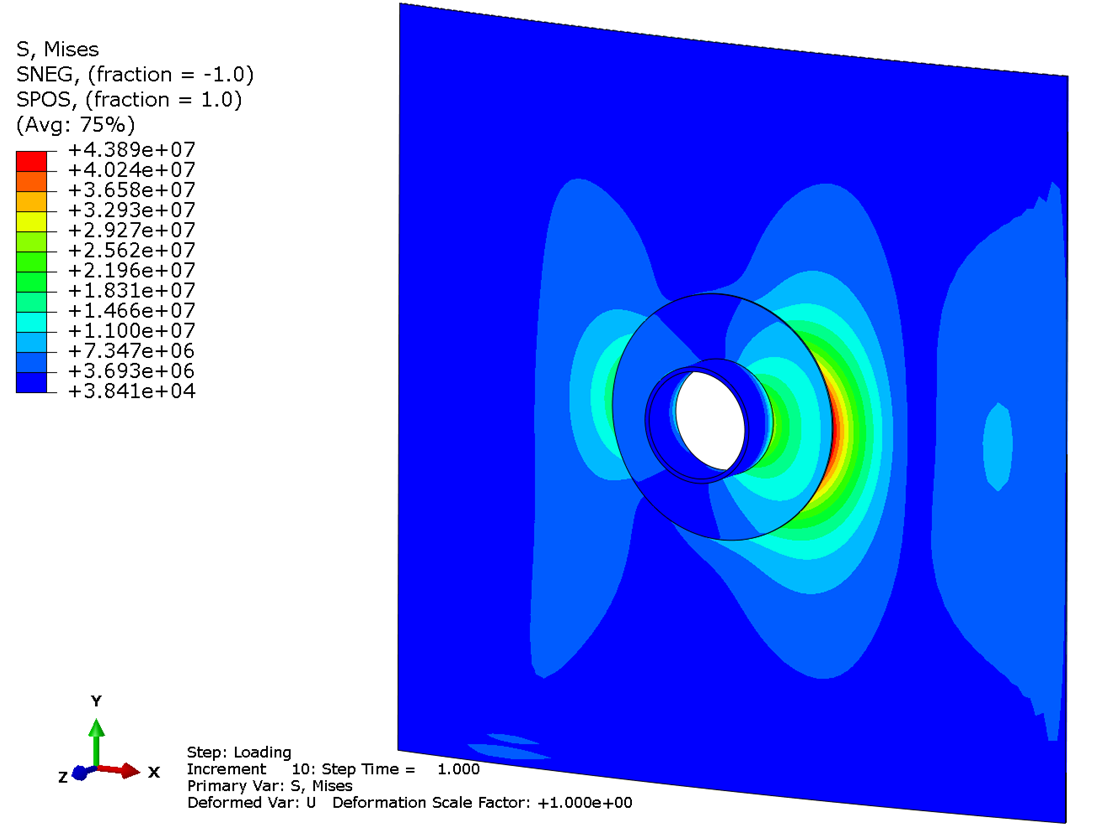

Finite Element Analysis (FEA)

Analysis of strength, stress, and vibration to ensure the reliability of mechanical systems.

Data Science

Transforming data into engineering insights using machine learning and predictive analytics.

Fitness-for-Service (FFS)

Assessment of structural integrity of industrial equipment to ensure safe operation.

Engineering Simulation

Virtual testing to validate real-world performance and accelerate innovation.

Failure Analysis

In-depth investigation into the root causes of equipment failure to prevent future incidents.

Predictive Analytics

Forecasting physical parameters (temperature, pressure, flow) using Machine Learning models to prevent failures and optimize processes.

Industry applications

Solutions tailored for your sector

Plant & Process

Vibration mitigation, failure analysis, efficiency improvements, and explosion modeling.

Building & Construction

Cleanroom air quality analysis, thermal comfort assessment, and stormwater management.

Energy

Turbine optimization, vibration analysis, performance prediction, and FFS for critical assets.

Product Design

Performance enhancement, reliability troubleshooting, and thermal management analysis.

Aerospace

Composite fuselage analysis, bird strike simulations, and weight reduction through topology optimization for flight components.

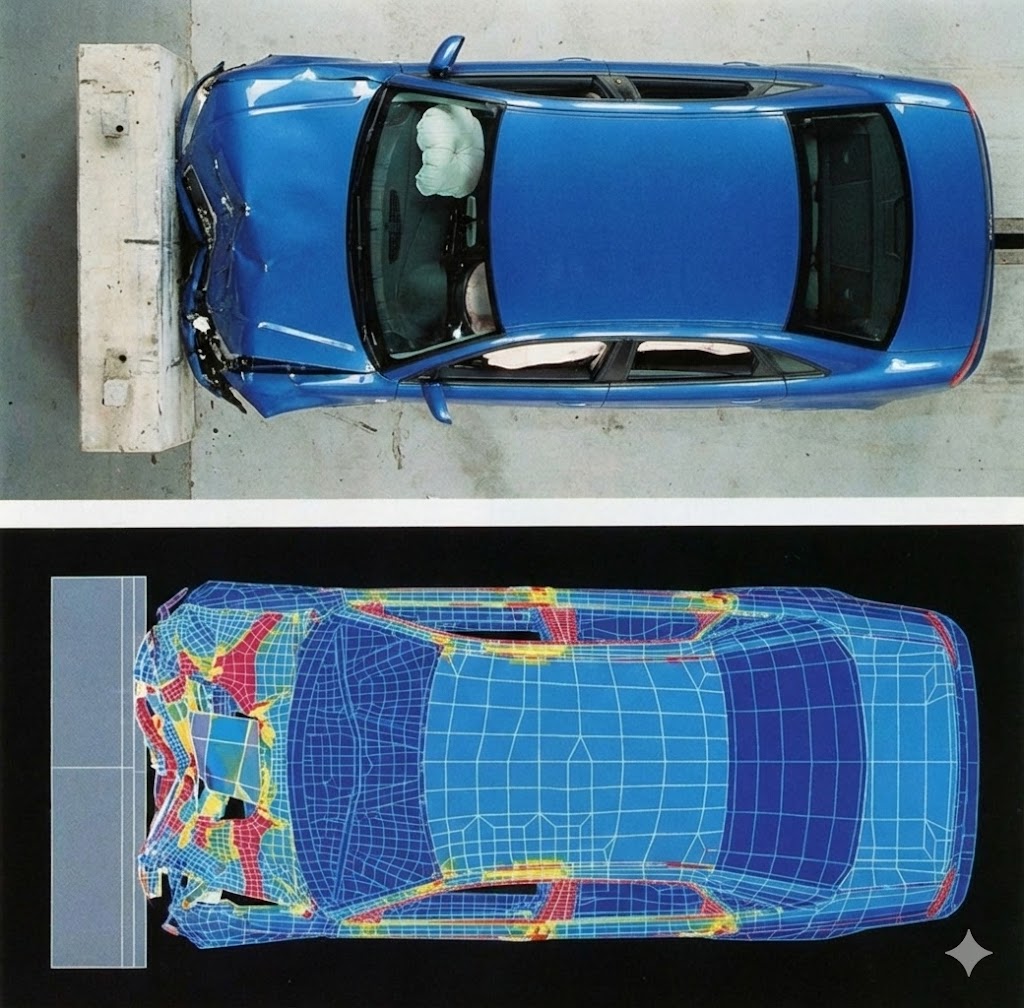

Automotive & EV

Battery thermal management, crashworthiness (explicit dynamics), NVH (noise, vibration, harshness), and tire-road interaction.

Medical & Biotech

Stent durability assessment, implant-bone interaction analysis, and simulation of drug delivery systems.

Electronics & High-Tech

Drop-test simulation, solder joint fatigue analysis, and thermal cooling optimization for PCBs and enclosures.

Case studies

A collection of projects demonstrating our hands-on capabilities.

Generative Design for Customer Production

Optimizing customer parts with generative design to achieve the lightest and strongest configuration while identifying design issues and validating structural integrity.

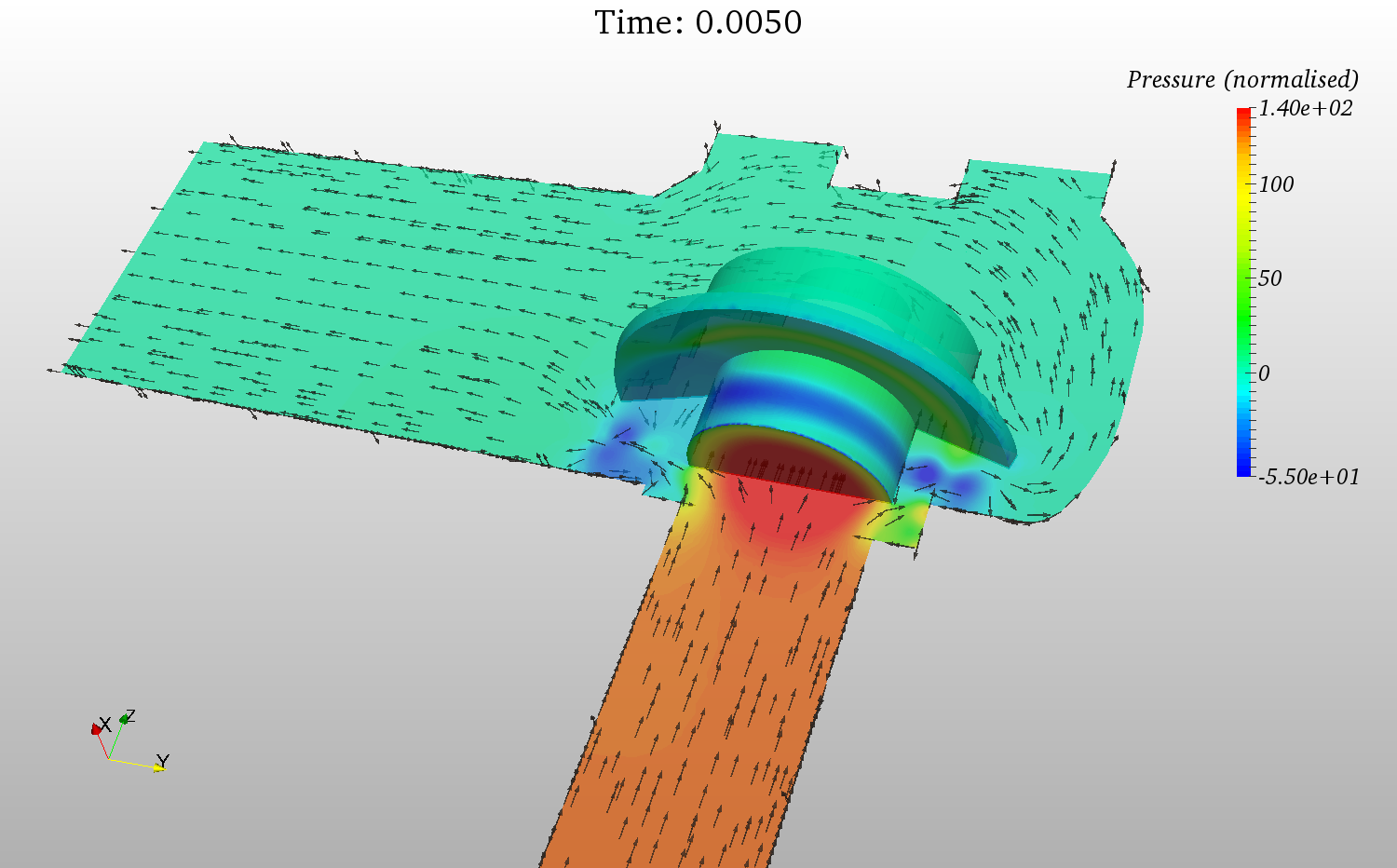

FSI Simulation of High-Pressure Relief Valve

Two-way Fluid-Structure Interaction analysis predicting valve flutter by coupling CFD flow with FEA structural response.

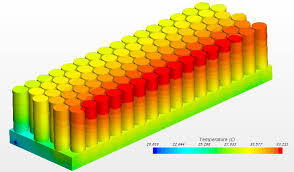

EV Battery Module Thermal-Structural Analysis

Coupled thermal-electric-structural simulation predicting battery swelling during rapid charging to optimize cooling and prevent thermal runaway.

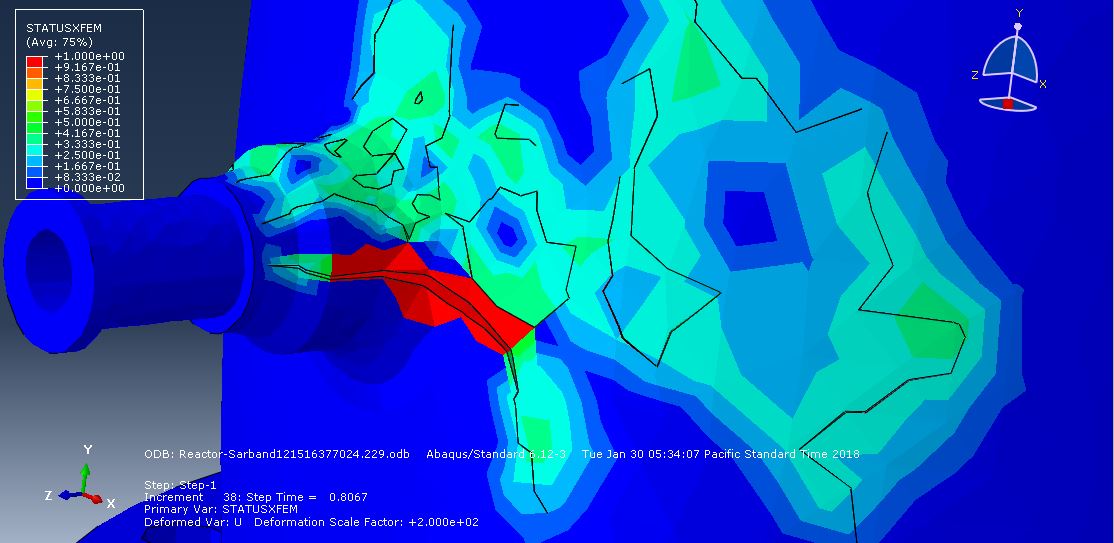

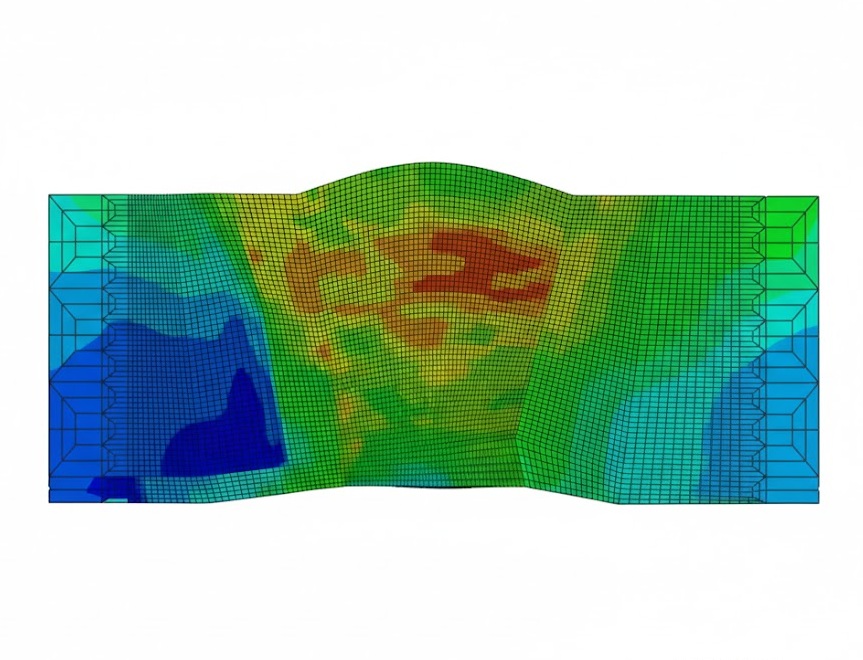

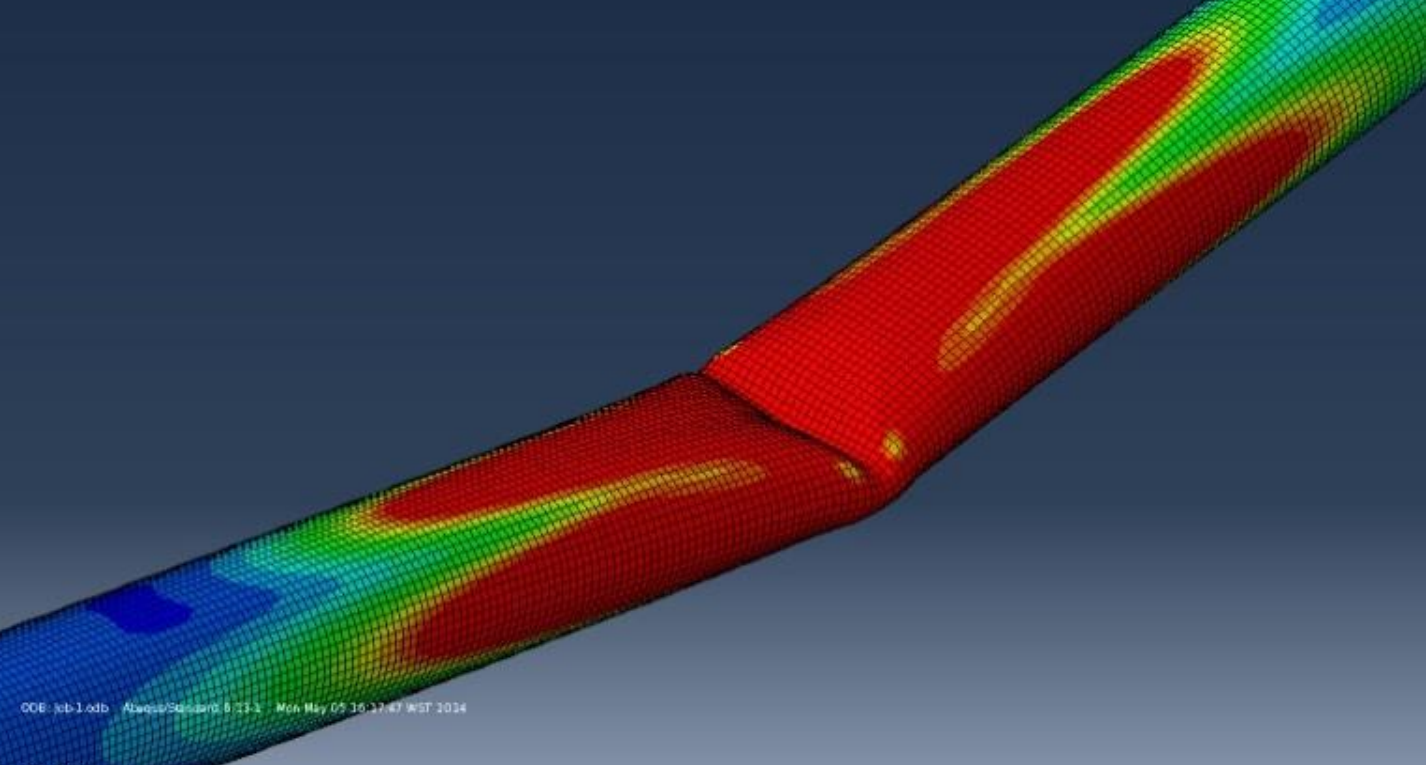

XFEM Crack Propagation in Pipeline Weld

Extended Finite Element Method simulating crack growth in pipeline welds under cyclic loading to determine remaining service life.

Composite Delamination Analysis

Investigating interlaminar failure in carbon-fiber wind turbine blades using Cohesive Zone Modeling and Virtual Crack Closure Technique.

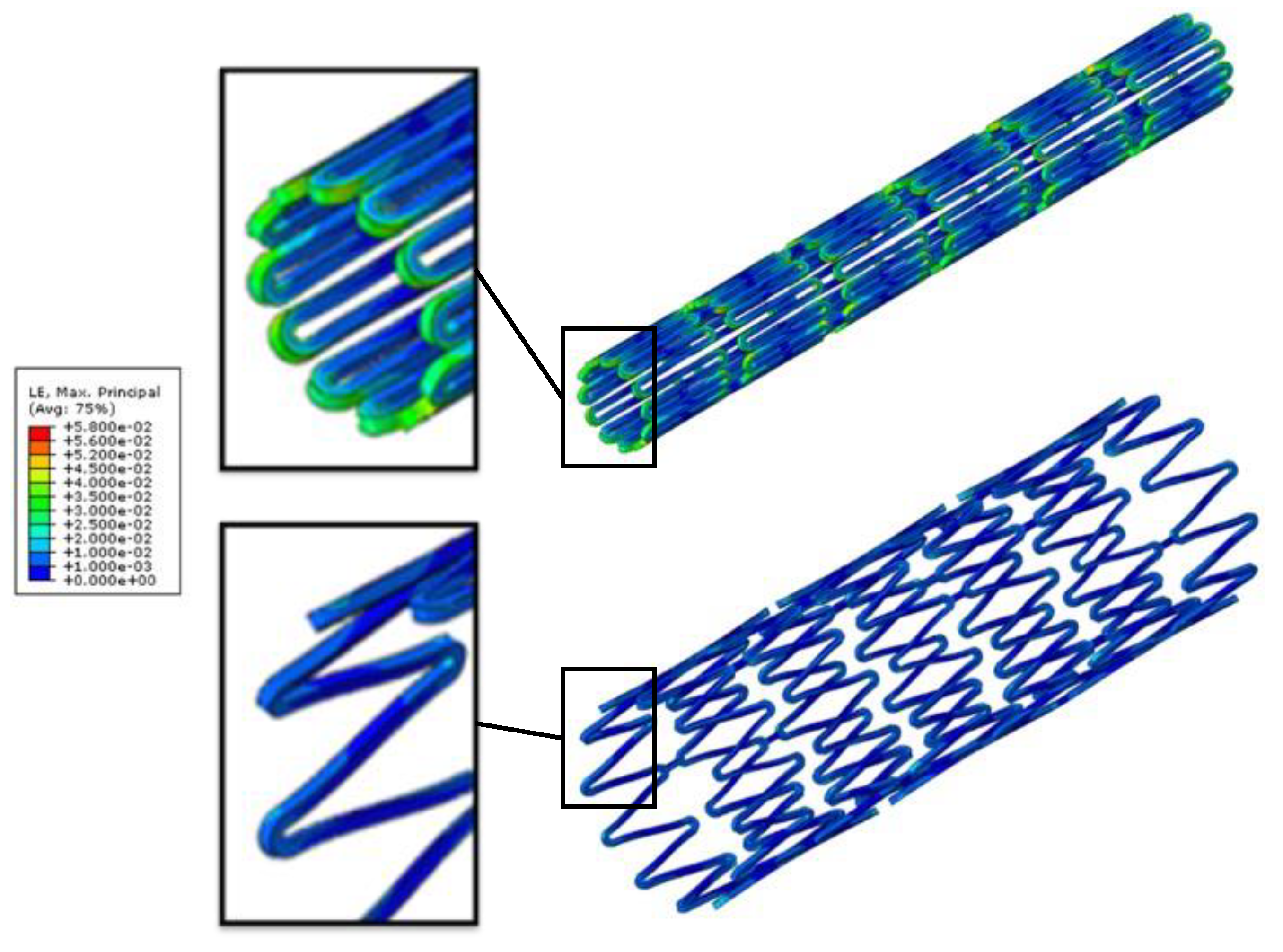

Nitinol Stent Fatigue Life Assessment

Simulating self-expanding heart stent durability with superelastic Nitinol material behavior to ensure 10-year performance under pulsatile pressure.

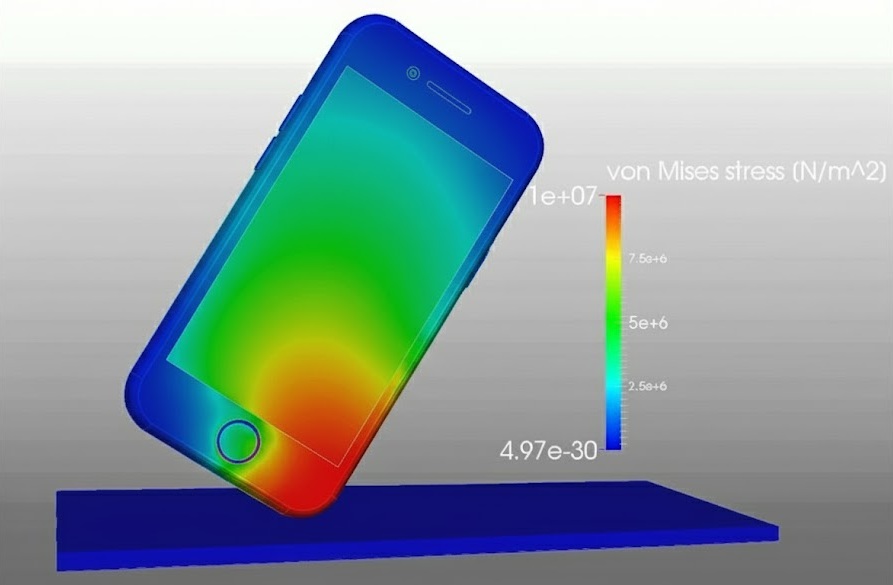

Drop Test & Impact Simulation for Customer Products

Explicit dynamics modeling drop and impact scenarios for customer products, predicting component fracture and separation with accurate material behavior.

Topology Optimization of Aerospace Bracket

Topology optimization reduced a titanium aircraft bracket weight by 40% while maintaining stiffness, designed for 3D printing.

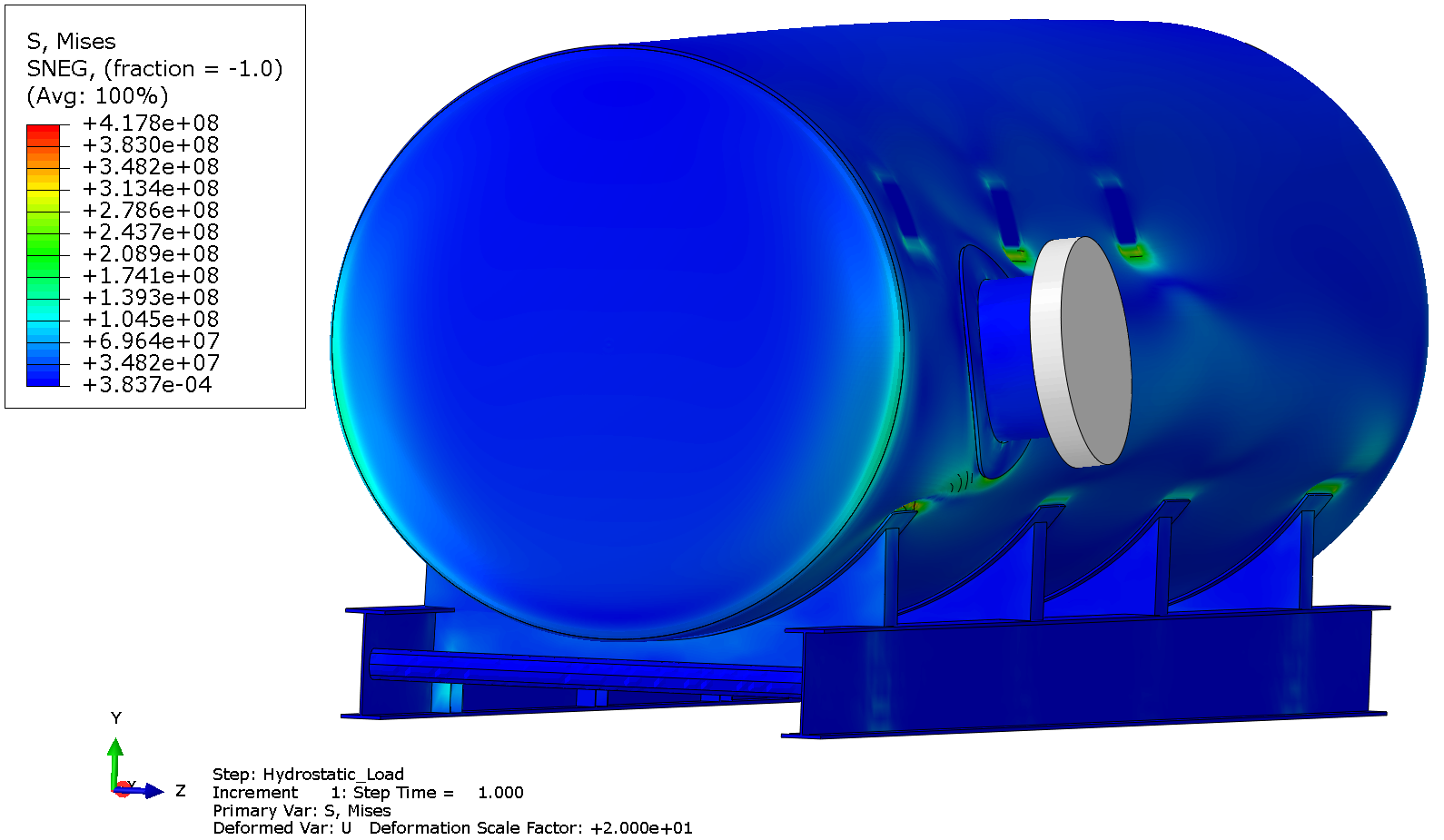

FEA Stress Analysis of Horizontal Tank

Evaluation of an existing GOST-compliant tank to identify shell strength after modifications and assess lifting lug capacity, leading to the design of new, safer lugs.

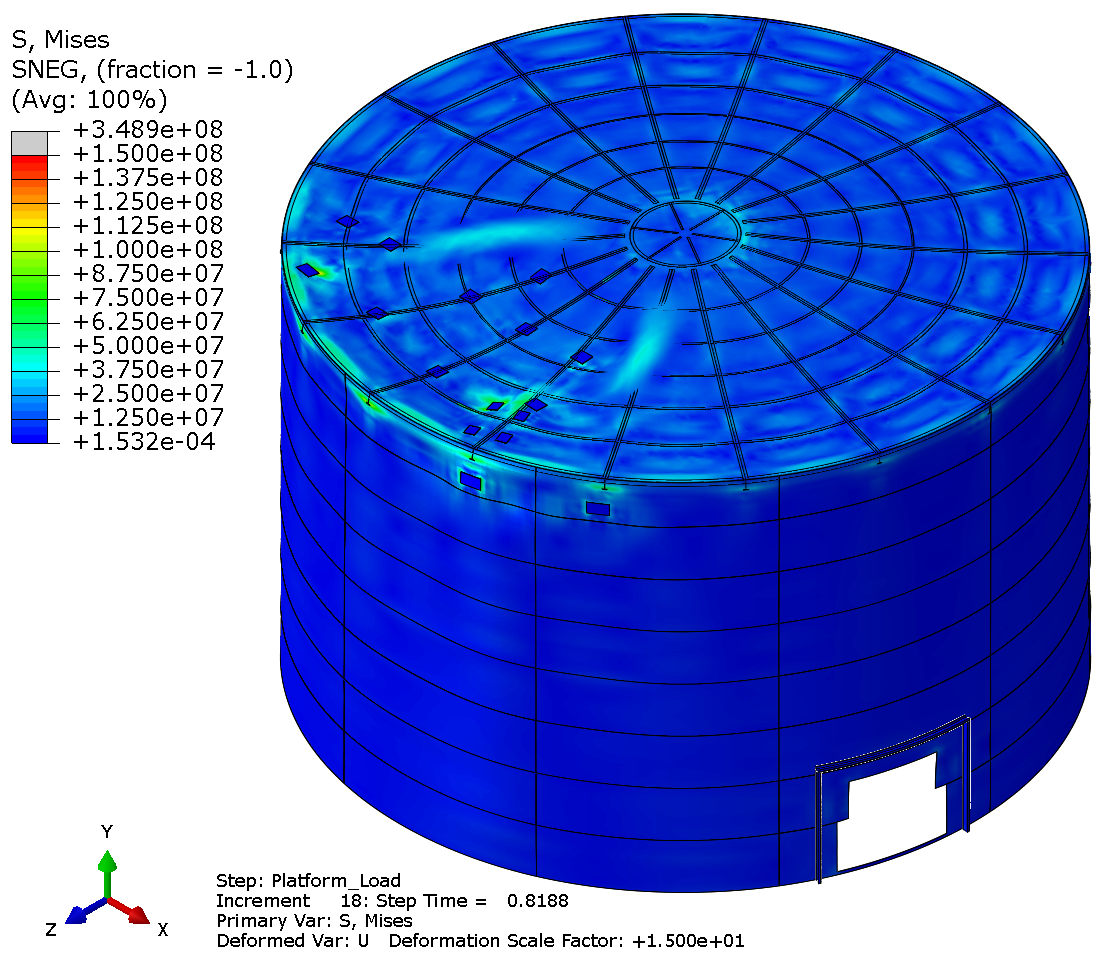

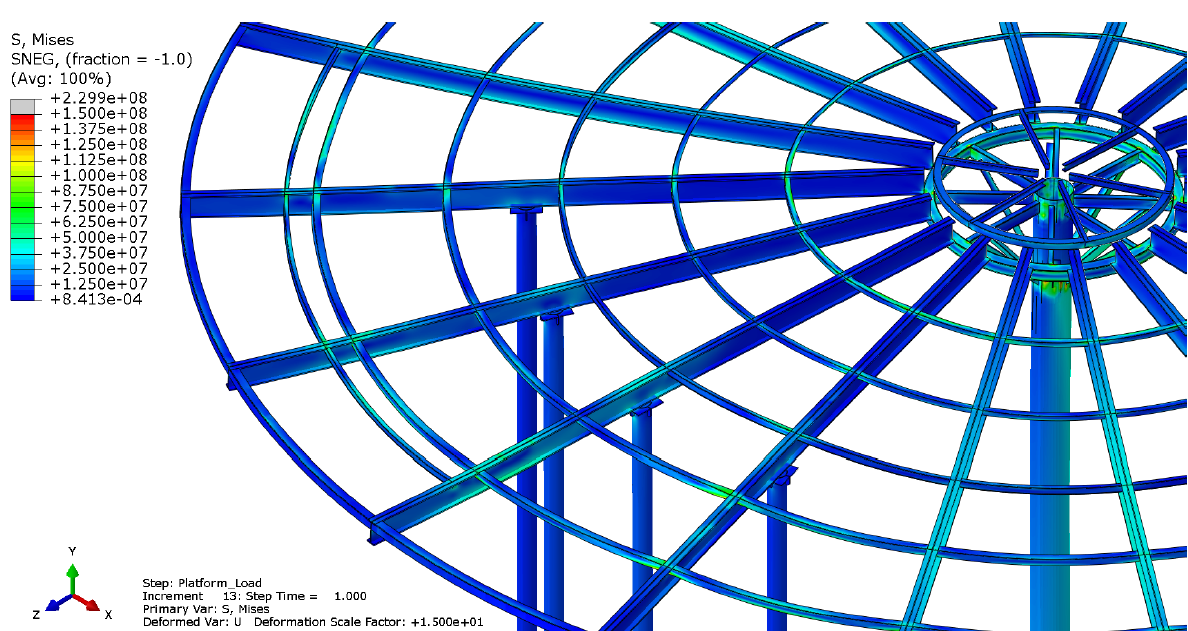

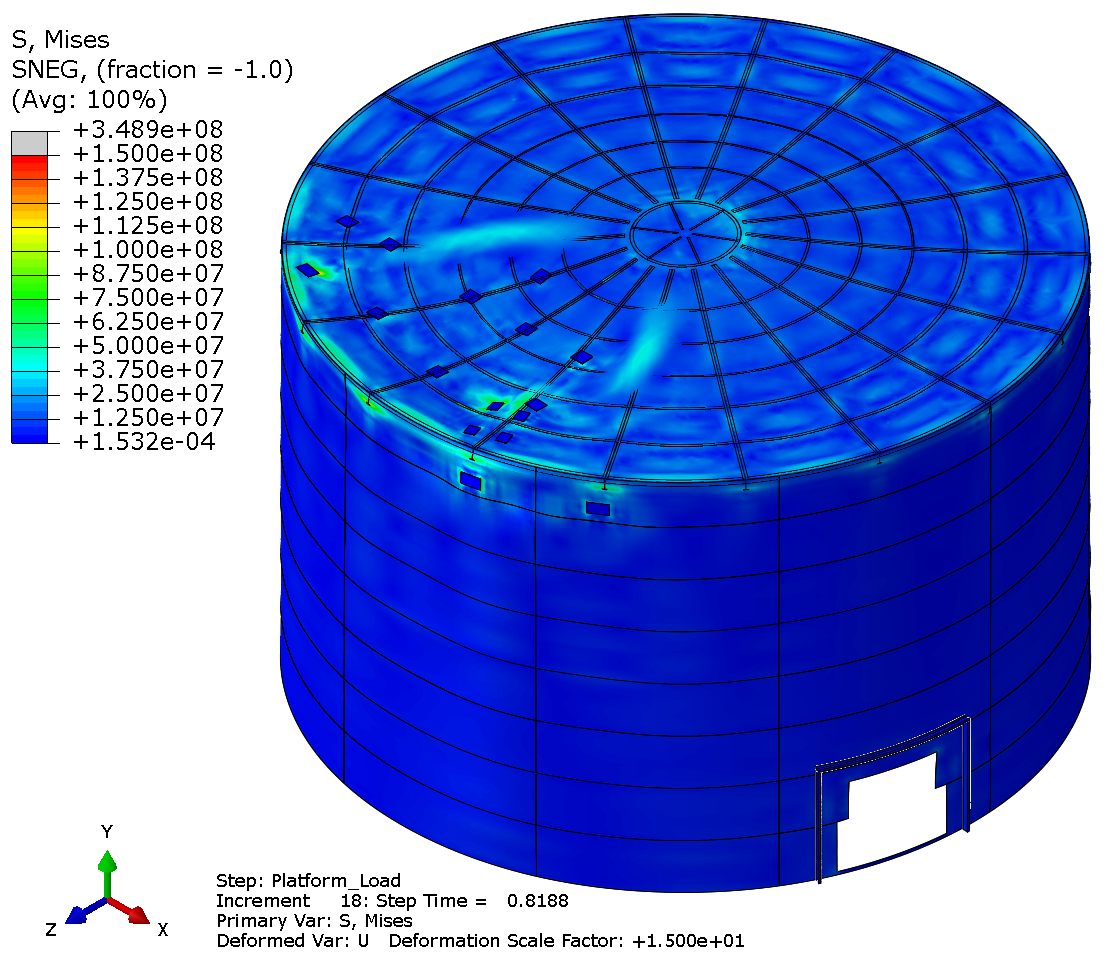

FEA for Tank Roof Reinforcement

FEA was used to analyze a corroded tank roof's capacity to support new equipment, resulting in reinforcement with new columns to prevent potential collapse.

Safety Analysis for Tank Door-Sheet Cutting

CFD and FEA were combined to simulate wind loads and stresses to ensure that cutting a new door in a corroded tank shell was safe for subsequent repair work.

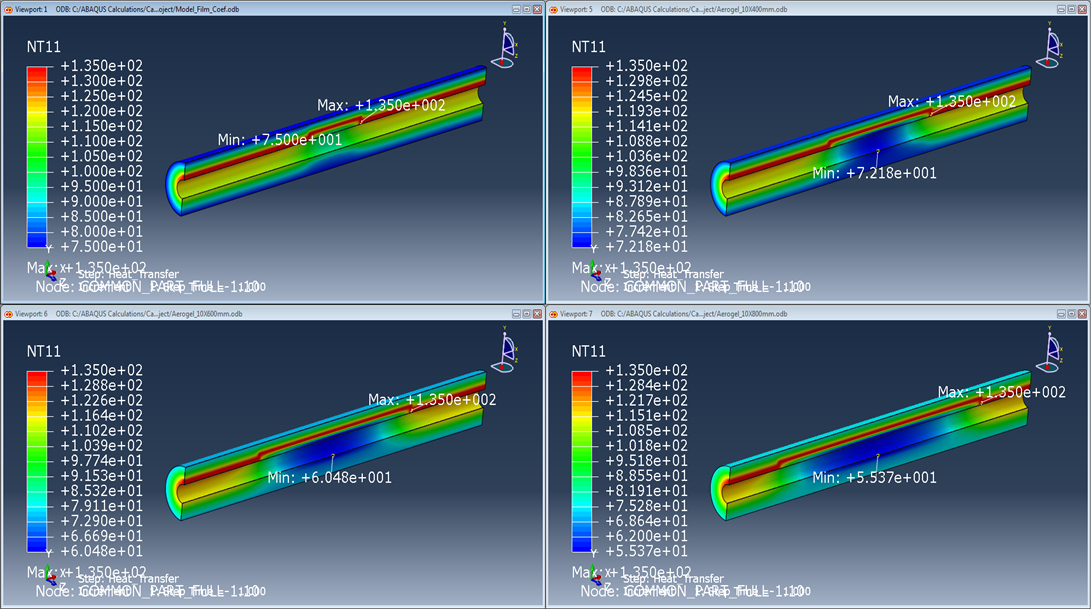

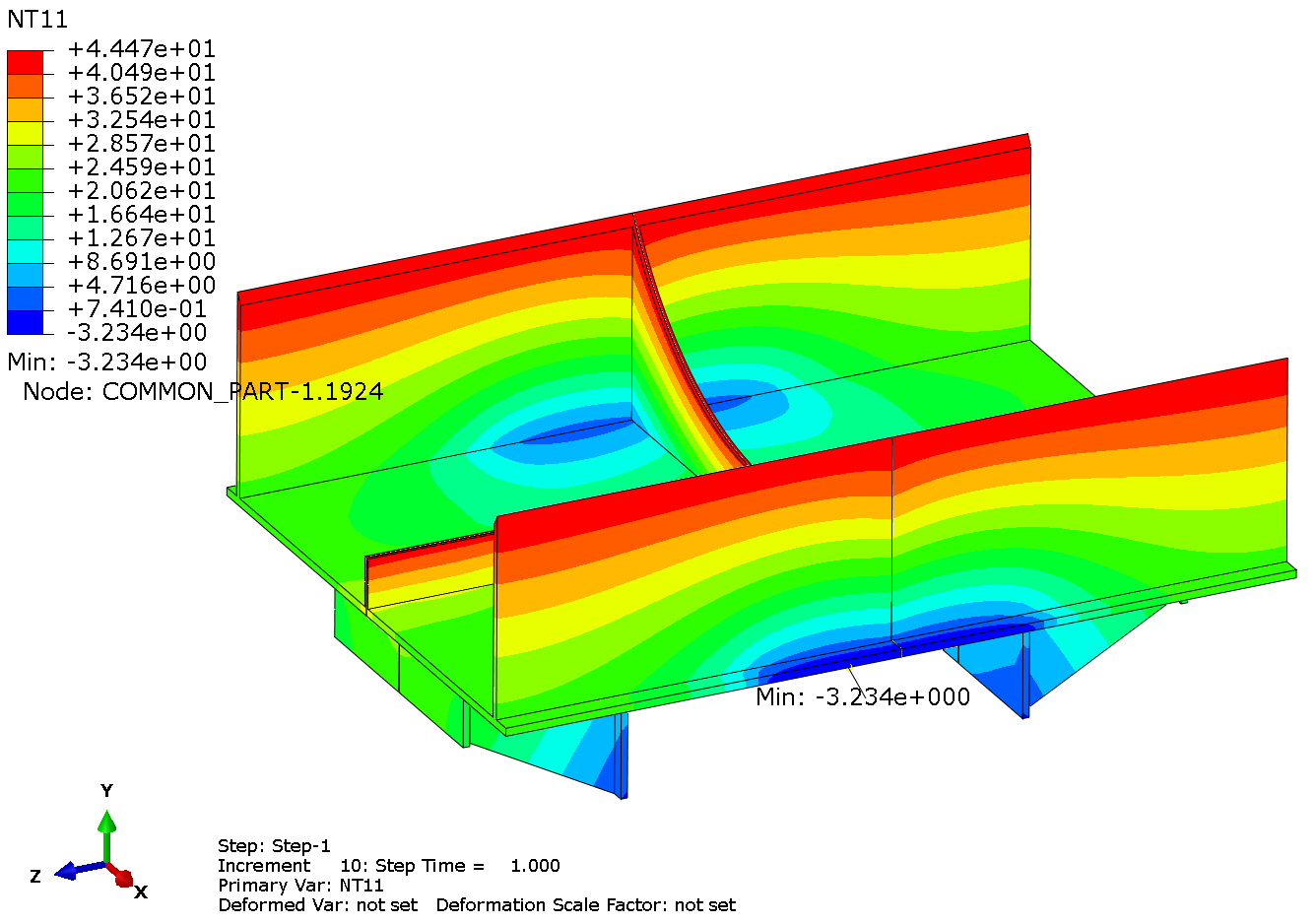

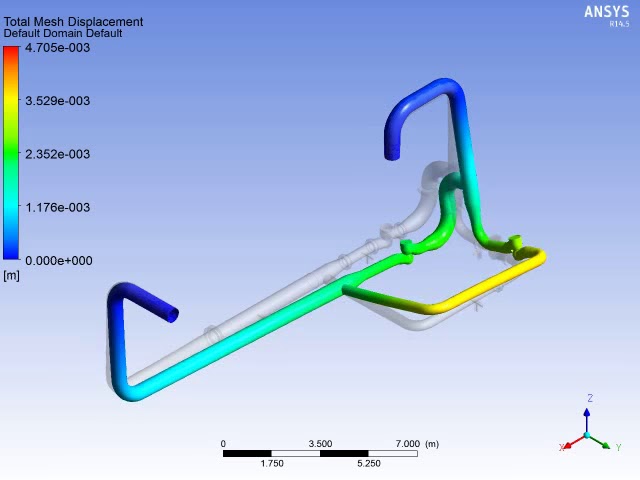

Thermodynamic Simulation of Heated Piping

A thermodynamic simulation was used to analyze overheating risks in trace-heated pipes, leading to a design that prevents Caustic Stress Corrosion Cracking (CSCC).

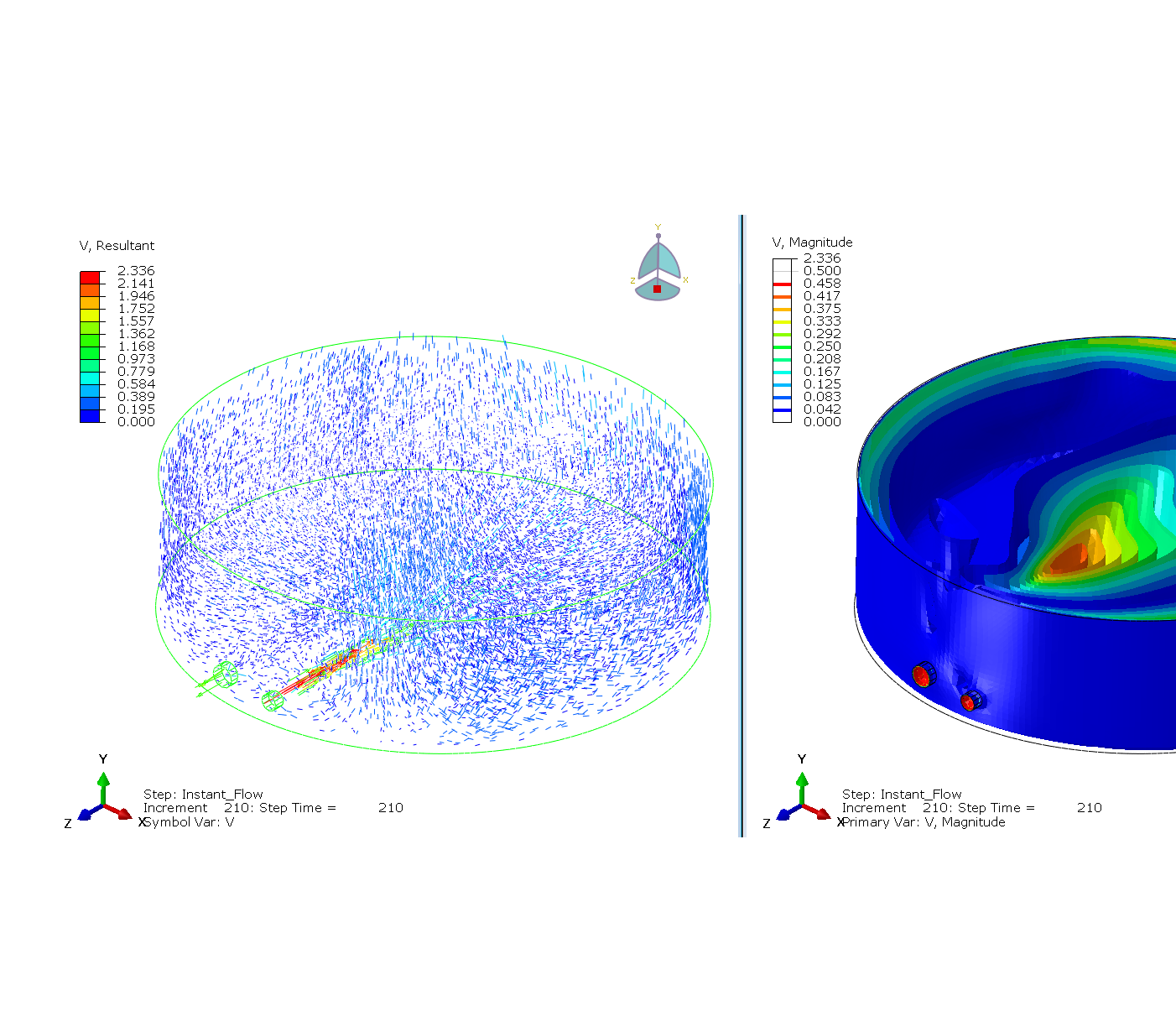

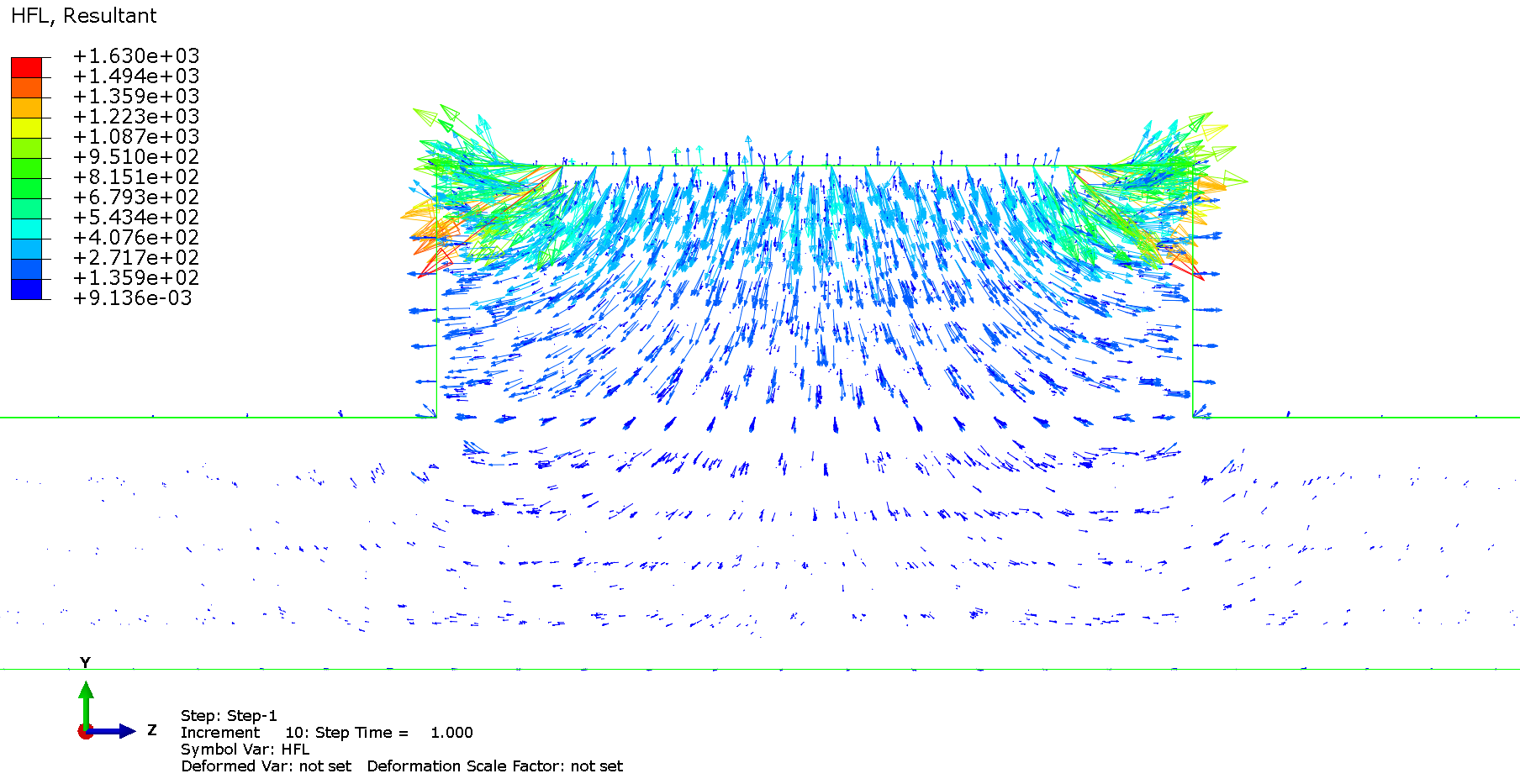

CFD Analysis of Tank Mixing Efficiency

CFD analysis verified that the close placement of inlet/outlet nozzles would not cause a 'short circuit,' ensuring complete and effective fluid mixing within the tank.

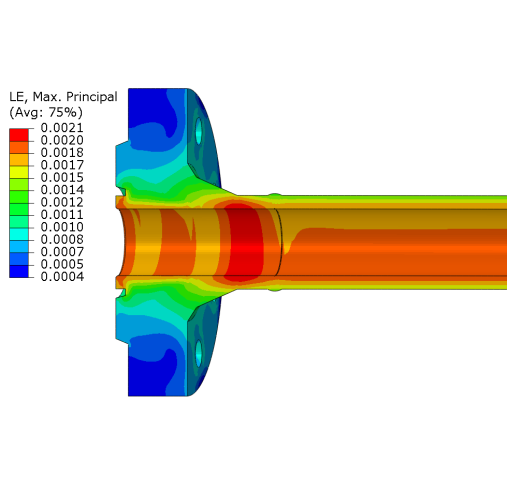

Advanced FEA for Flange Joint Integrity

FEA provided detailed strength checks for flange joints where conservative ASME methods indicated failure, avoiding costly piping redesigns in constrained 'brownfield' areas.

FEA Verification of New Nozzle Loads

FEA was used to determine the allowable loads for new nozzles on an existing tank, ensuring the tank shell's integrity and eliminating the risk of rupture.

FEA Optimization of Pipe Trunnions

Where conservative standard calculations were not applicable, FEA was used to verify trunnion capacity, optimizing piping layout and reducing material costs.

Strength Evaluation of Anchor Support

An anchor support was found to be made from incorrect steel. FEA was used to determine its actual load capacity, leading to a decision to replace it for safety.

Low-Temperature Analysis of Pipe Support

FEA thermodynamic analysis was used to evaluate a support made from steel not rated for low temperatures, preventing potential brittle fracture during winter operation.

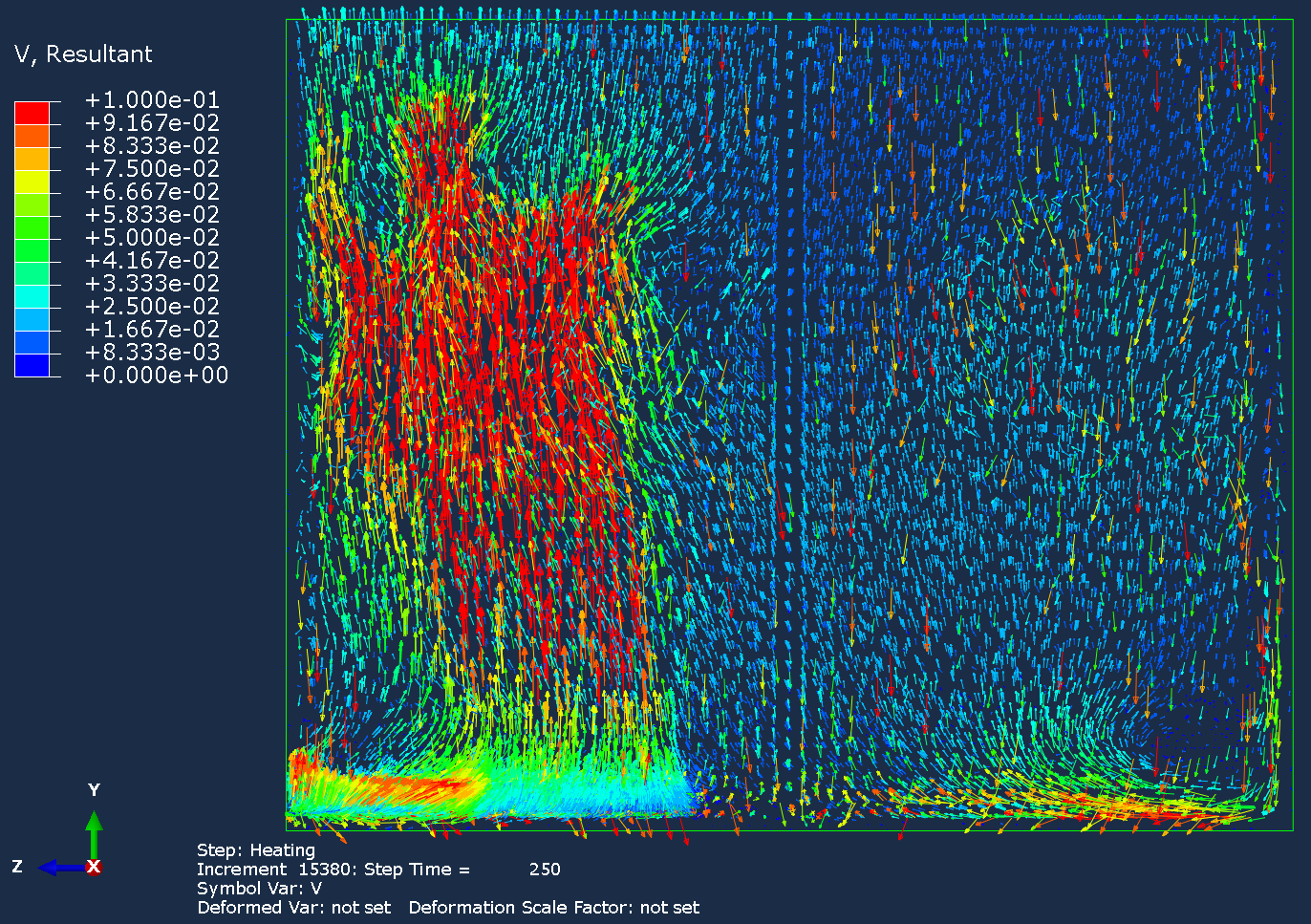

CFD Simulation of Hydrotest Heating

CFD was used to model the temperature distribution in a water tank with a steam coil during a hydrotest in cold weather, verifying the test procedure's safety.

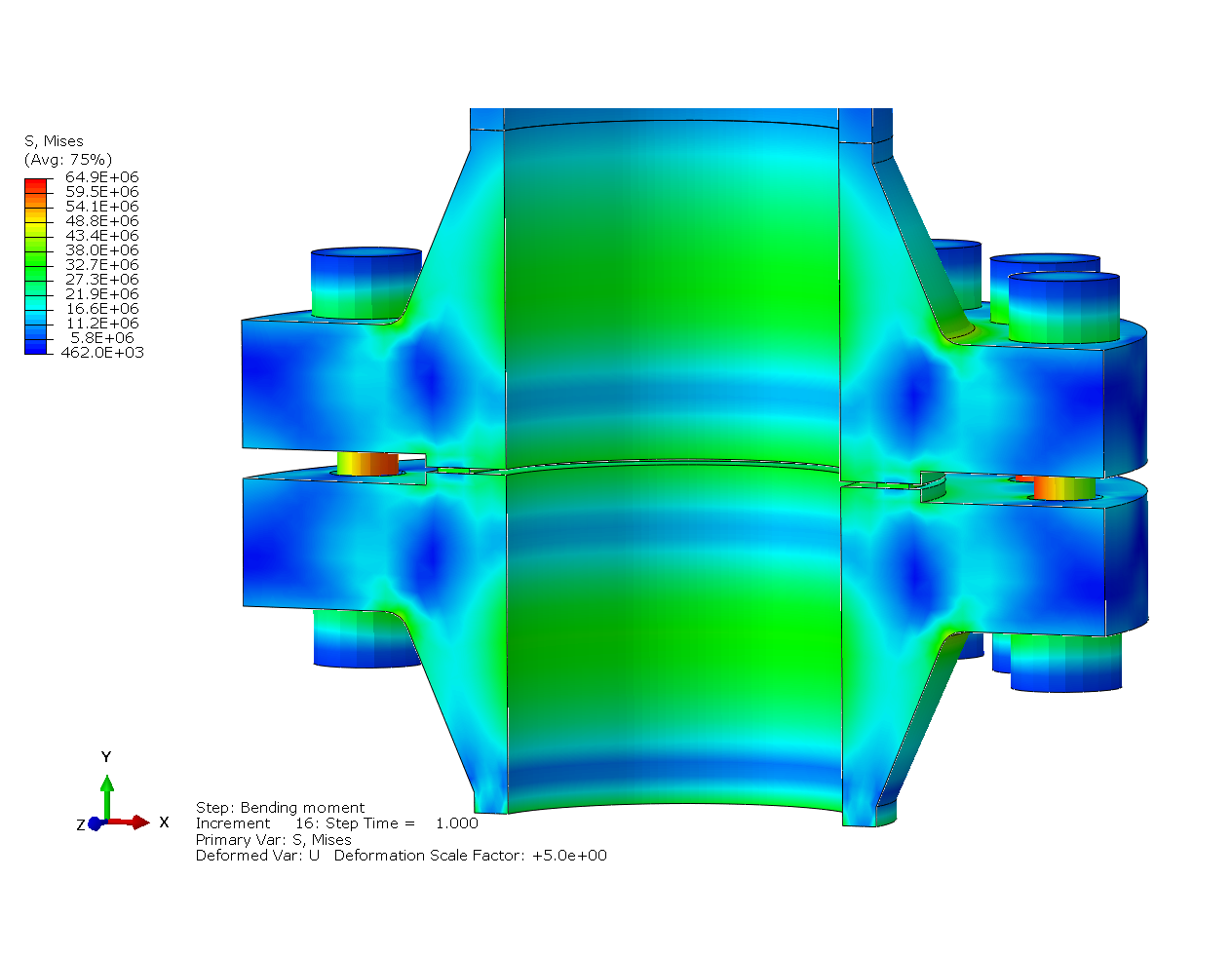

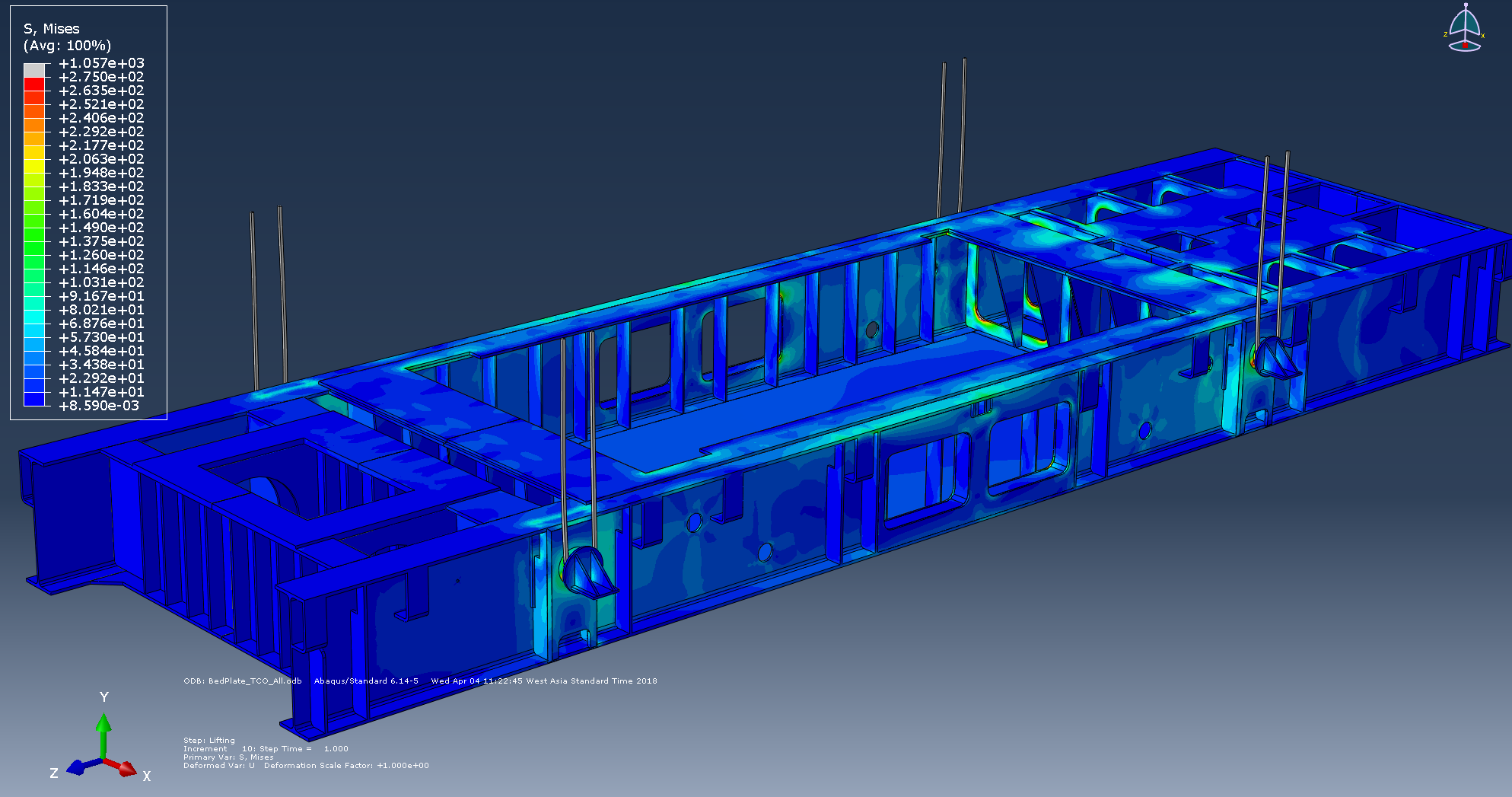

Lifting Analysis of Generator Frame

FEA was performed to check stresses on a generator frame and its trunnions during lifting. The analysis showed that lifting must be done element by element to avoid failure.

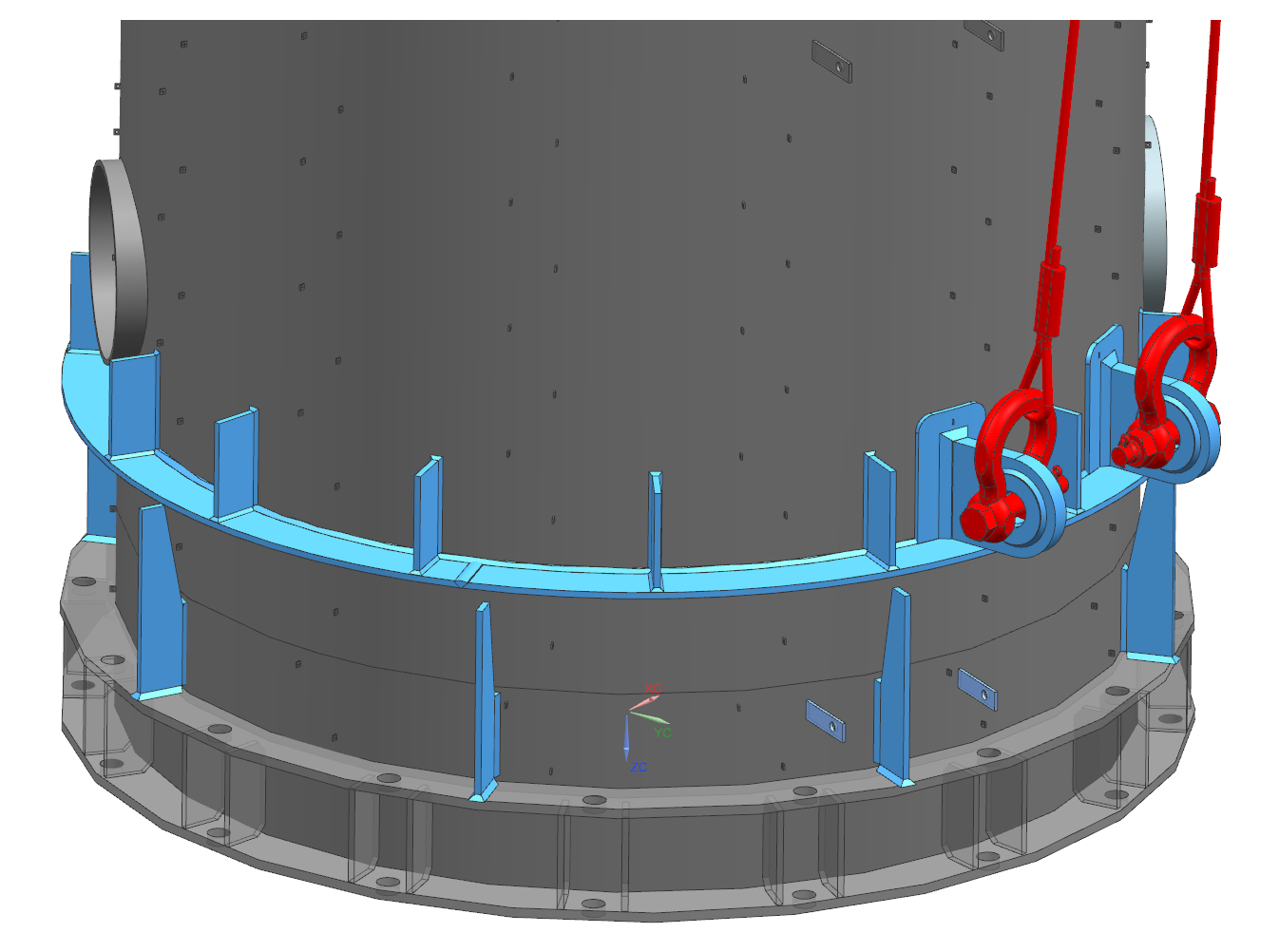

Lifting Beam & Tailing Lugs Stress Analysis

FEA analysis of stress concentrations in cut holes from lifting beam and tailing lugs to ensure safe crane lifting operations.

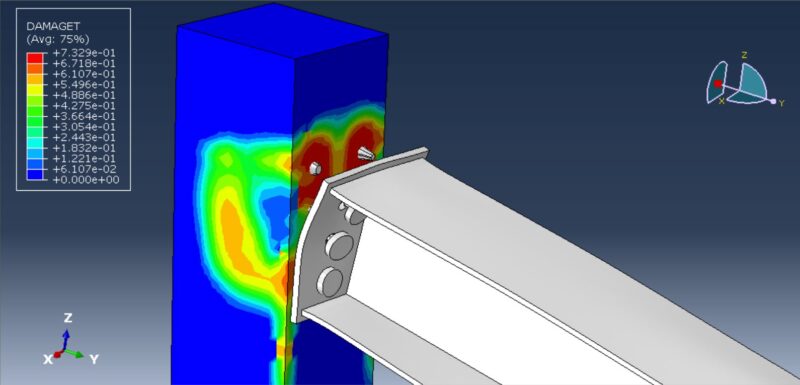

FEA of a Steel Beam-to-Column Connection

A detailed FEA was performed on a critical moment connection for a multi-story steel building. The analysis verified the connection's integrity under maximum load...

Flowline Buckling Analysis

Following the primary stress analysis of a high-temperature pipeline, additional FEA buckling calculations were performed at critical locations to verify structural stability under operational loads...

FIV/AIV Analysis for Process Piping Integrity

A comprehensive Flow-Induced and Acoustically-Induced Vibration (FIV/AIV) assessment was performed on a critical gas piping system...

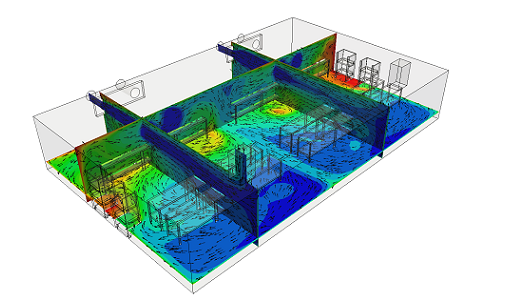

CFD Optimization of Cold Room Airflow

To resolve inconsistent temperature zones in a pharmaceutical cold storage room, a CFD analysis was performed. The simulation visualized airflow patterns and thermal distribution...

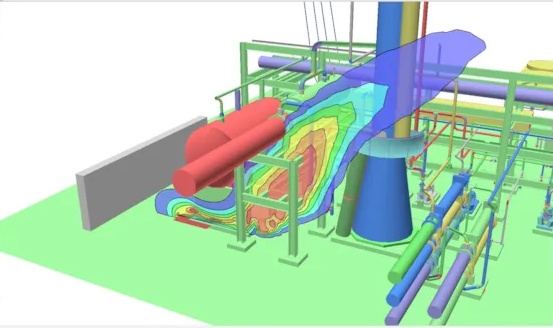

Hazardous Gas Dispersion & Consequence Analysis

A consequence analysis was performed for a petrochemical facility to model the dispersion of a hazardous gas release...

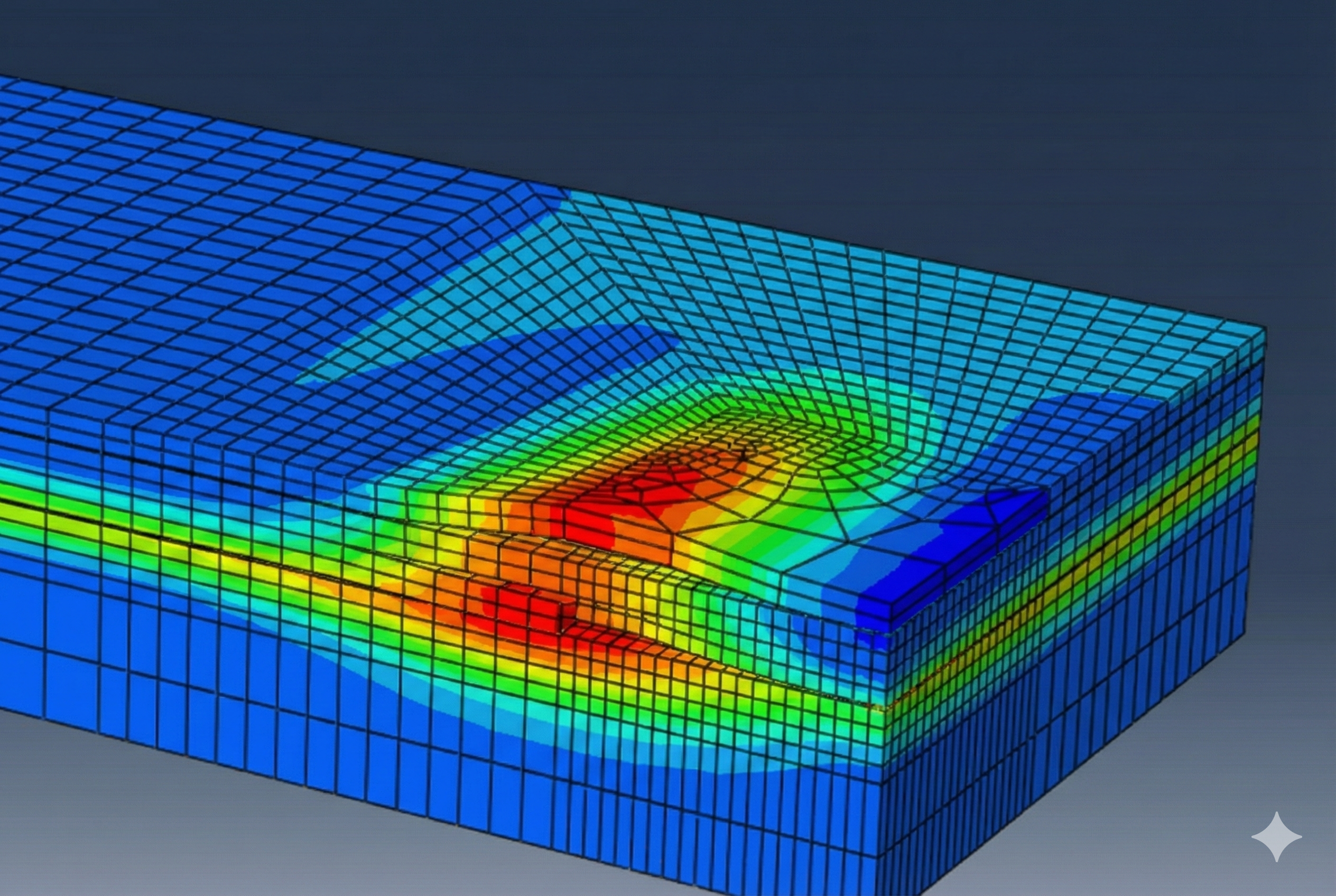

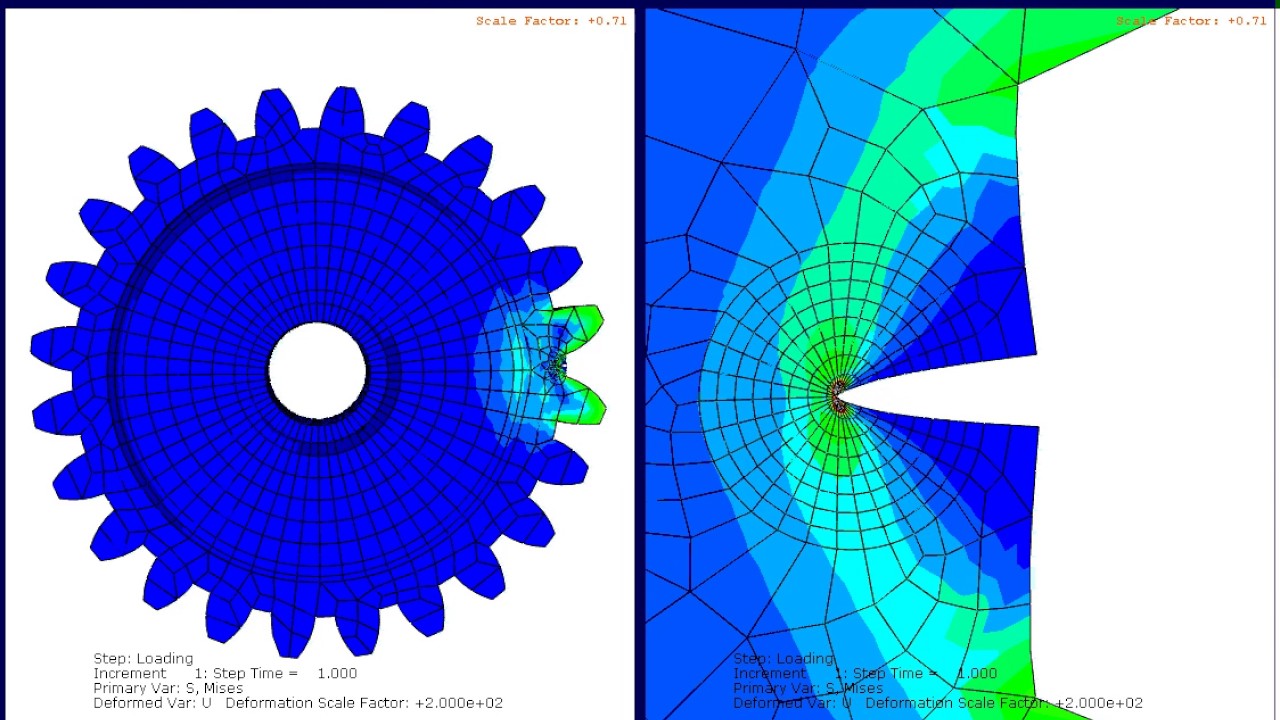

Gear Tooth Crack Propagation Analysis

To determine the service life of a critical gearbox component, an FEA-based fracture mechanics analysis was conducted...

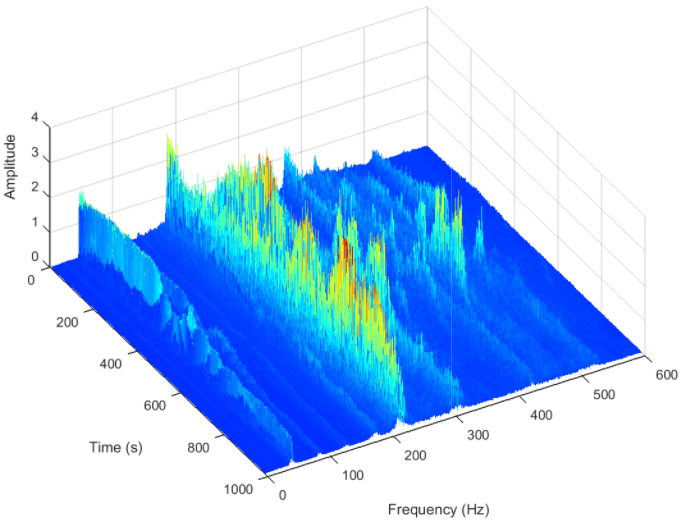

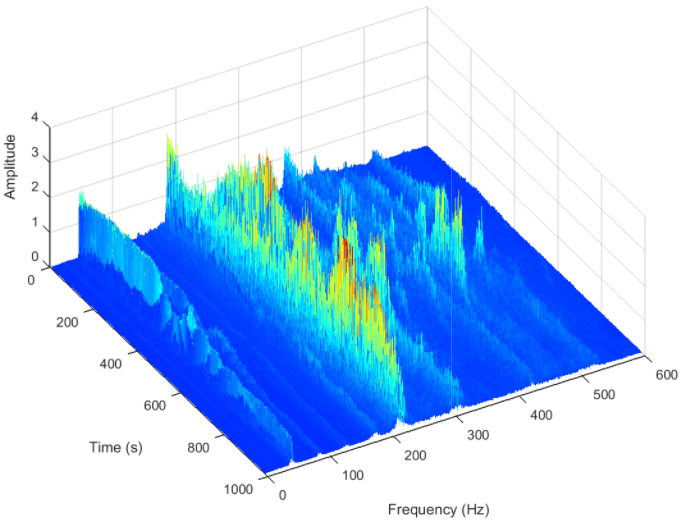

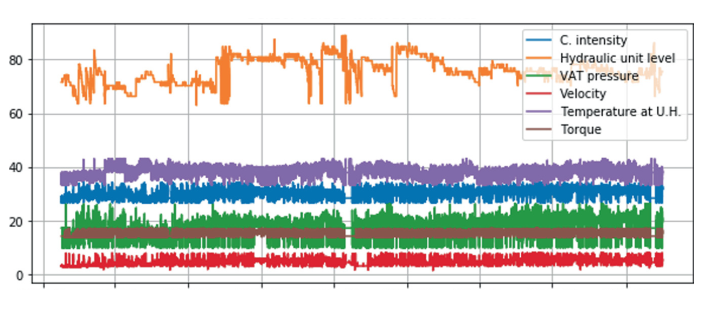

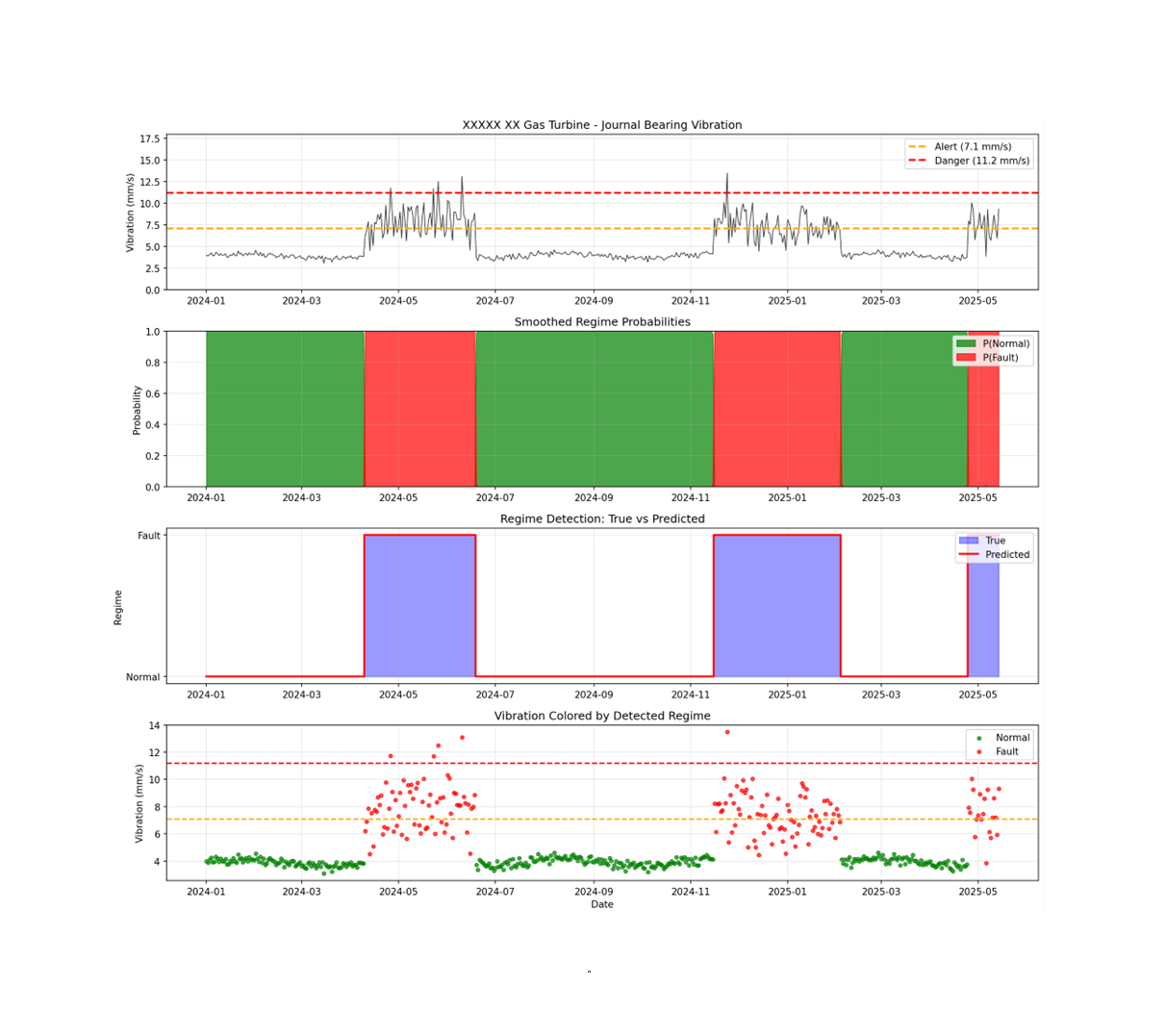

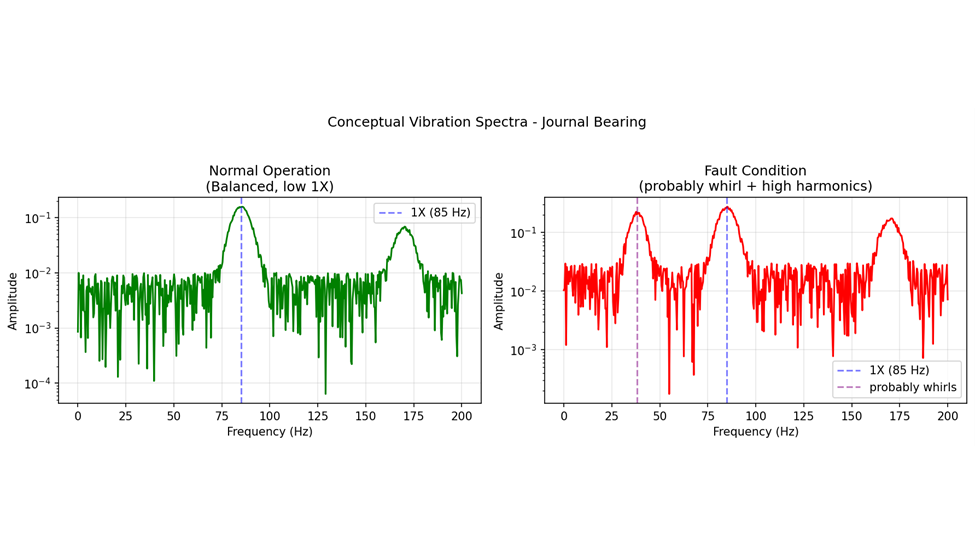

Gas Turbine Bearing Condition Monitoring

Probabilistic vibration monitoring system using Bayesian online change point detection for real-time turbine bearing diagnostics with 97.9% accuracy.

Automated Bearing Regime Analysis

Machine learning model for automated classification of gas turbine bearing operating regimes achieving 94.8% accuracy in regime separation.

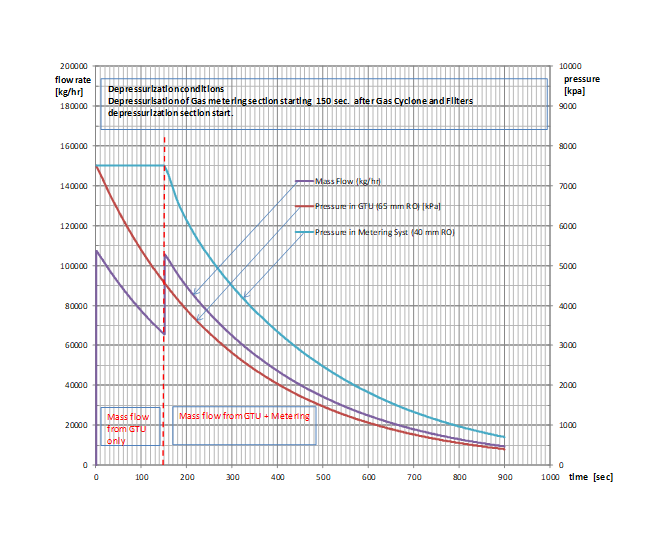

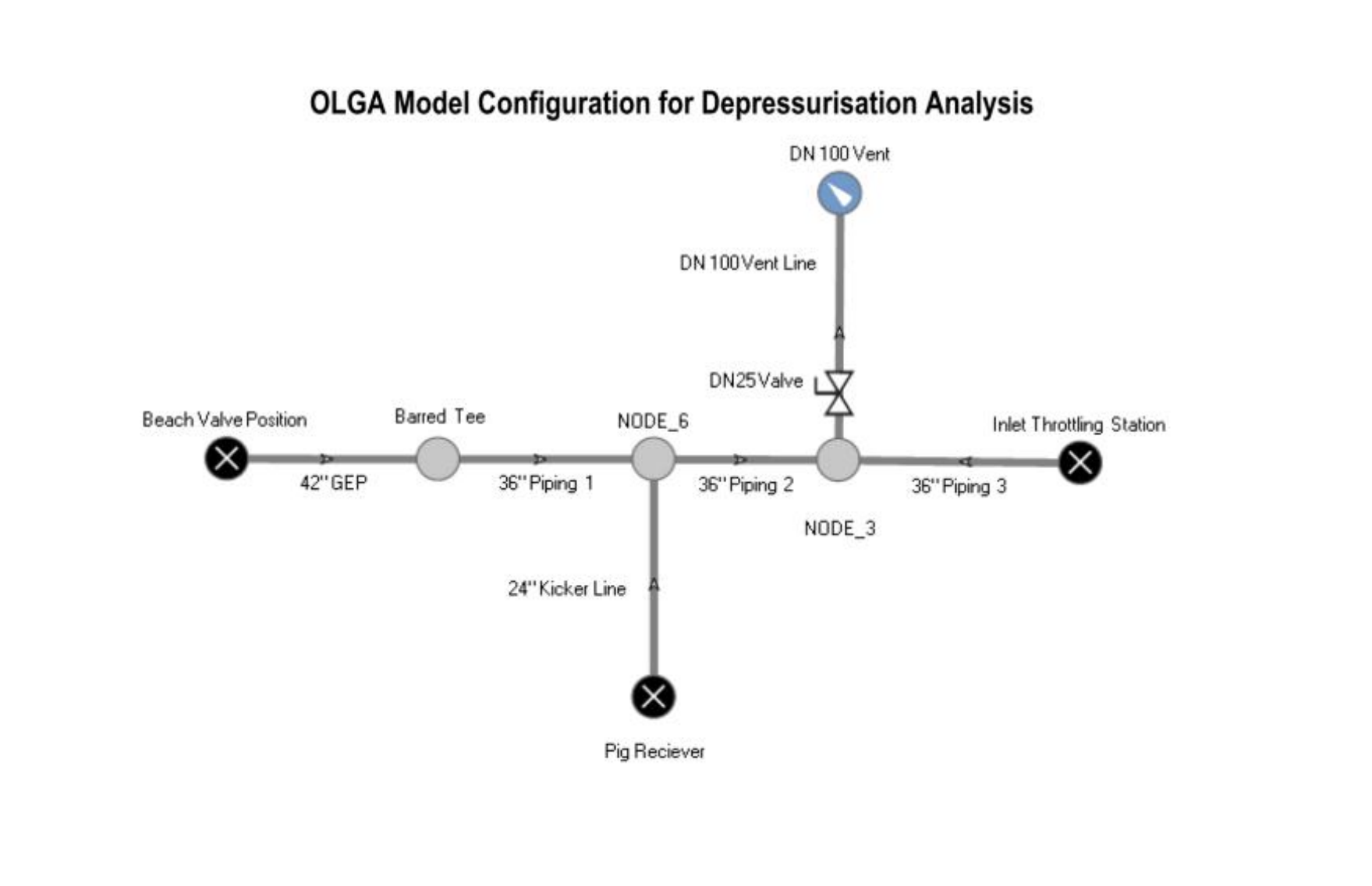

Emergency Gas Blowdown Simulation

OLGA transient simulation optimizing emergency blowdown valve sequencing to meet API 521 requirements while limiting peak flow to 105,000 kg/h.

Pipeline Depressurization Thermal Analysis

OLGA simulation determining minimum wall temperatures during offshore gas pipeline depressurization to prevent brittle fracture risk.

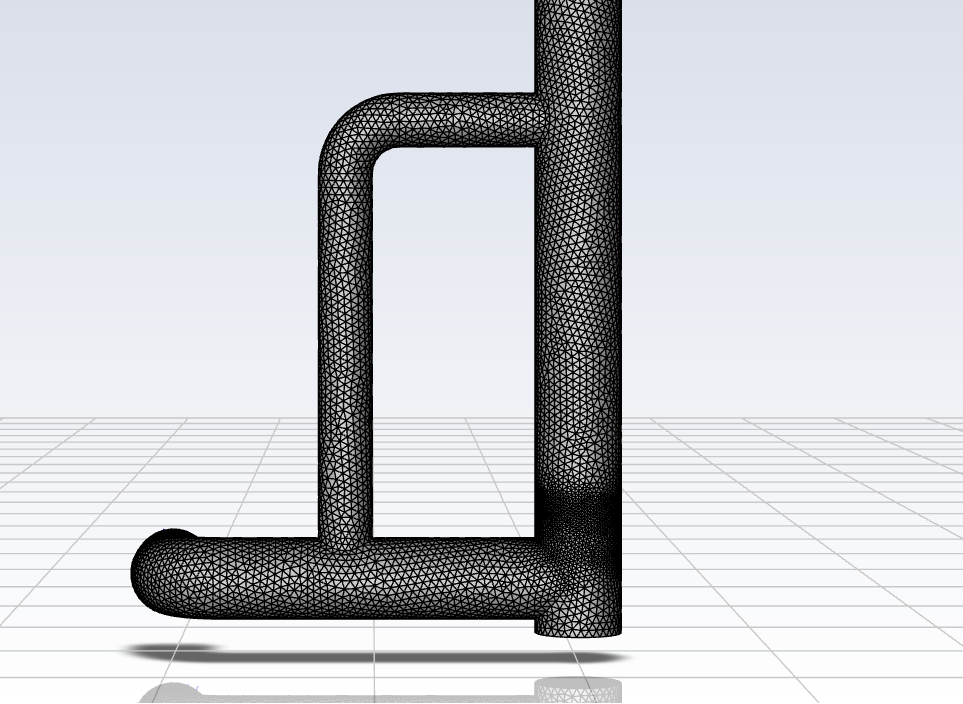

PIG Launcher Chamber Conversion Analysis

Fluent CFD analysis enabling conversion of 8 PIG receiver chambers to dual-purpose launcher/receiver operation on main gas pipeline.

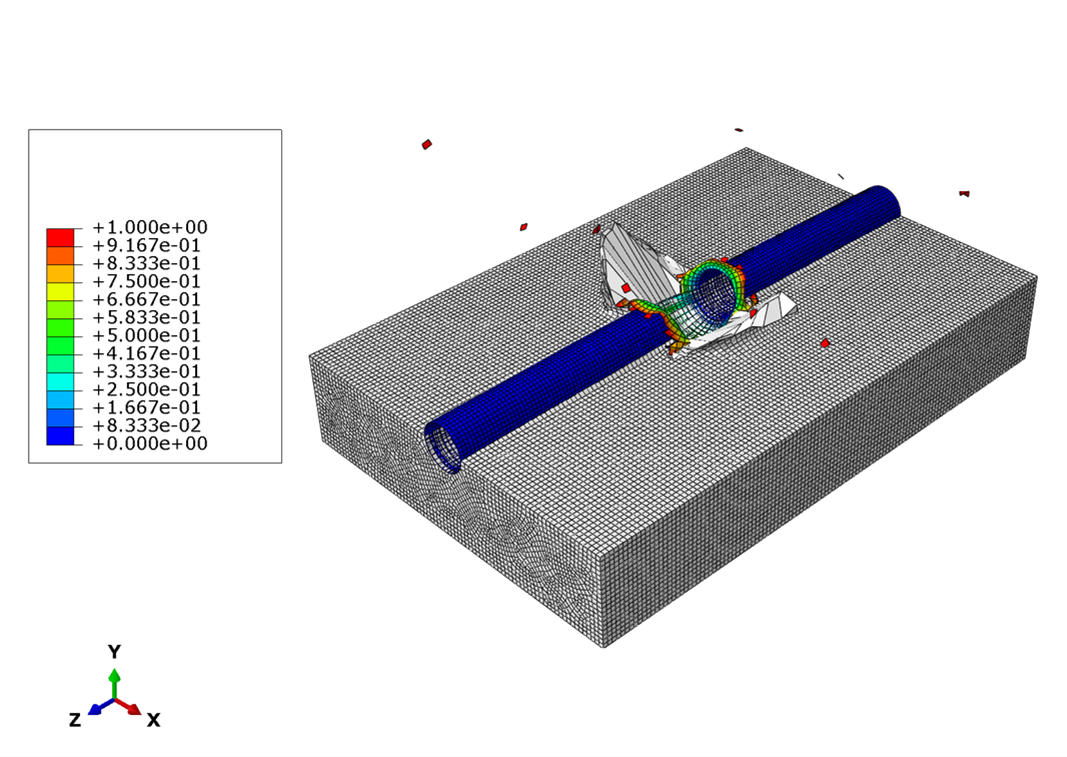

Pipeline Rupture Consequence Analysis

Coupled gas dynamics and FEM simulation of guillotine pipeline rupture predicting fragment trajectories up to 1883m for emergency zone planning.

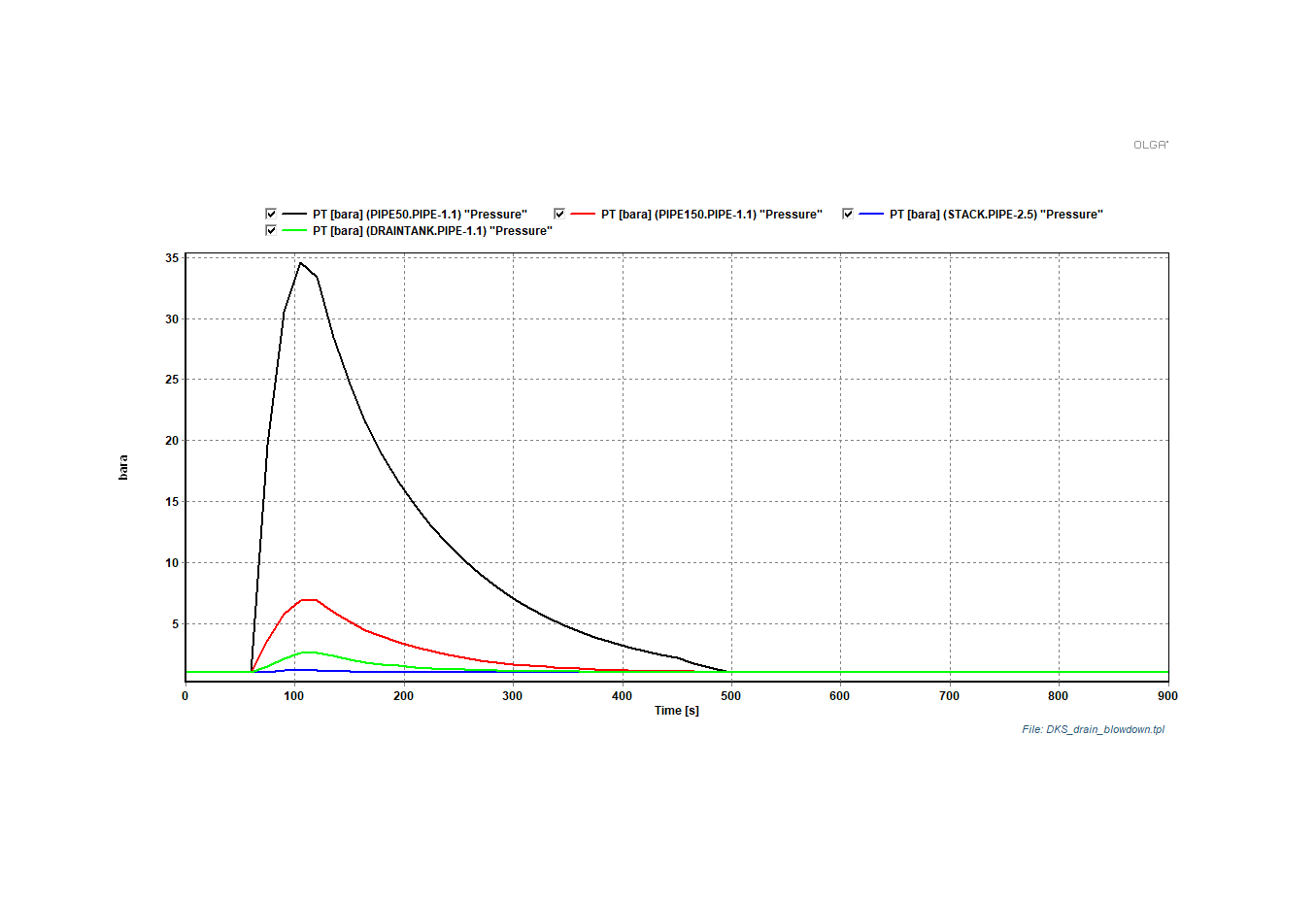

Compressor Station Drain System Analysis

OLGA simulation of booster compressor drain system capacity identifying critical vent upgrade requirement to DN325 for safe operation.

What our clients say

Trust backed by results

Proactive Leadership and Engineering Excellence

"What stood out most was Ilya's proactive and solution-oriented approach to challenging technical problems. He consistently demonstrated a high level of ownership, sound engineering judgment, and collaborative spirit, ensuring that all deliverables met quality standards and project deadlines. He had an opportunity to get leadership on facilitating all technical discussions with CTC experts, which was so helpful to expedite project decisions by providing required input and directions for other supporting Engineers on the chain of this process. Ilya's performance on this project truly reflects his strong professional discipline and commitment. He is a valuable team member whose contributions significantly enhanced the project outcome." more

Dedication and Competence in Every Challenge

"It has been few days since the pressure faded away from delivering the last of Phase IIA Pre-FEED project, NCOC. I believe we now have all documents issued & accepted, fetched in. On this note above, I just wanted to express my gratitude to each of you for the effort and patience you have shown and helped us with on this project. Despite the difficulties and challenges, the delivered piping and mechanical work has witnessed your perseverance, dedication and discipline competency which can only be complimented for." more

Project Progress Recognition

"I wanted to recognize your efforts and helping overall team to path forward D-503.2 column progress." more

Excellence in 3D Modeling

"I would like to thank your colleague Yerlan Akylov for the excellent work he has done in preparing a 3D model of the actual state of the Mixing Chamber 62-C-501. A lot of work has been done by Yerlan, all the details of which he, on his own initiative, coordinated with us (the Reliability) at all stages… I am surprised that you have done so much high-quality work involving specialists from different departments of TCO... Considering all of the above, it was very important to display the current state of the Mixing Chamber and cover and measure all areas of deformation to justify the replacement of it in the next mechanical window. Thanks to your meticulous approach and awareness of the importance of this model for the Reliability, Yerlan managed to work with all the details taken into account." more

Clever Solution & Cost Savings

"Andrei provided a very clever solution of rerouting of the SEP manifold piping which has contributed in the overall reduction of 300 meters of steam jacketed piping. This has resulted in a net savings of $ 1.8 MM to the bottom line. His suggestions also removed the prospect of overloading the existing pipe racks. Andrei is being recognized for his accomplishment and stepping out to make things happen. His willingness to put his suggestions forward is greatly appreciated." more

Recognition Certificate for Collaboration

"Recognition Certificate presented to Andrey Pak. TCO Projects Management would like to express our gratitude for the effort you put in your work in 2010. Your commitment to your work helps the project team to stay on track and on target to meet their goals. Your colleagues have identified you as the key person who is the joy to work with, the most helpful, willing to share your knowledge, contributed a lot to improve team spirit and your safety leadership is recognized by your group. Thank you for all your hard work during a very eventful year. Thank you for your seamless collaboration between your project team, between projects and TCO." more

Our team of Experts

Expertise you can trust

Amangali N. Nysangaliev

Chief Technical AdvisorAcademician of the National Engineering Academy of the Republic of Kazakhstan | Doctor of Technical Sciences | Professor | Member of Doctoral Dissertation Defense Council | Scientific works primarily devoted to improving calculation methods for strength and stability of oil and gas pipelines

Ilya Rozov

Lead Mechanical Stress EngineerMaster's degree, Gubkin Russian State University, Machinery and Equipment for Oil and Gas Industry | Expert in CAESAR II | Specialist in FEA and CFD.

Ivan Vassilenko

Machine Learning EngineerMaster's degree in Applied Mathematics, Higher School of Economics (HSE University) | Bachelor of Applied and Computational Mathematics, Al-Farabi Kazakh National University (KazNU) | AI Tools for Heavy Infrastructure | Data Scientist | From Problem through Code to ROI.

Yerlan Akylov

Principal Mechanical Stress EngineerFaculty of mechanical engineering and robotics (Krakow, Poland), AGH University of Science and Technology | Bachelor's degree - Technological machines and equipment, Kazakh Agro-Technical University named after S.Seifullin | Specialist in Mechanical Design and Stress Analysis. PVeLite, Compress

Andrey Pak

Engineering ManagerMaster's degree, Atyrau Oil and Gas University, Mechanical Engineering | 25+ years of experience in Mechanical & Piping Engineering | Leader of Advanced Engineerig Group

Consult with our experts

Partner with our experts to ensure your project takes the right technical direction.

© 2025 Segmenta Group, KMGP company